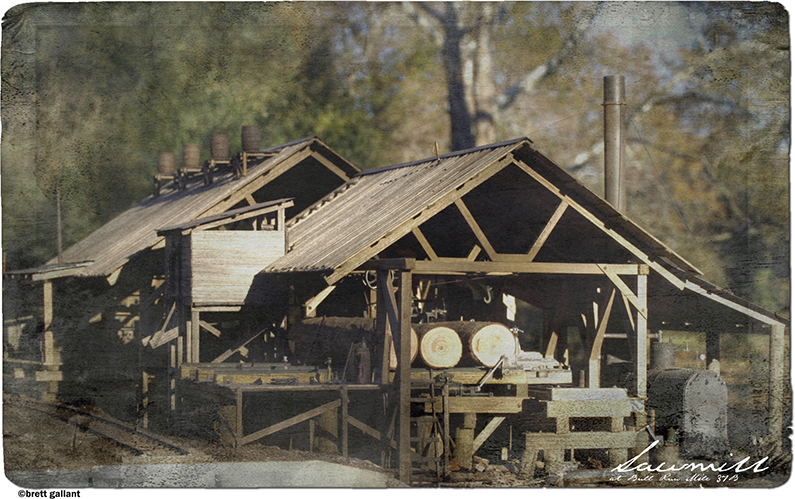

Pilot Models Constructed by Brett Gallant

Names, Logos, Designs and Photographs Owned and Copyright Brett Gallant

CHB Models Classics

O Scale Sawmill Machinery

Available as Individual Kits or Sets

Now Shipping

Kits Include White Metal, Resin, and 3D Printed Details

All Kits Completely Updated with 3D Printed Parts

Individual Kits Include a Link to Download Instructions

Full Sets Include a Printed Manual

Since 1995, SierraWest Scale Models has been the undisputed leader the world over in hand-poured resin and white metal detail castings. With emerging 3D Printing technology, SierraWest continues this tradition of unparalleled dedication to quality and innovation. Utilizing custom high-strength tooling resin, SWSM 3D Printed detail parts are very durable and easily handled. Supports are removed here in the shop so you can enjoy the painting and weathering process. Replacement parts are sent fast and free if you damage or lose a part. A small shipping and packaging fee may be added to cover costs. Be sure to check back often for the addition of new details.

Every attempt is made to keep the items listed for sale on this page in stock. Please allow between 3 and 10 business days to package and ship your order. Allow additional processing time for orders that are outside the USA and Canada. All items are in very limited quantities and once sold out the "add to cart" button will indicate "out of stock". Items will be restocked as time permits.

click here to visit the SierraWest Instruction page

All the basics on working with SierraWest 3D Printed parts

as well as instructions for 3D Printed kits are available.

Click Here for Information

on the Award Winning O Scale Sawmill Project

WP-900

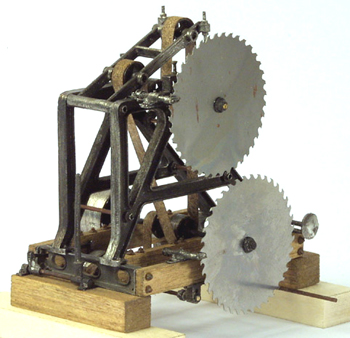

O Scale Single Blade Circular Husk

Includes White Metal, 3D Printed parts, and a laser cut sawblade. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Single Blade Circular Husk

WP-901

O Scale Circular Husk - Second Blade Option

Includes White Metal, 3D Printed parts, and a laser cut sawblade. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Circular Husk - Second Blade Option

WP-902

O Scale The Carriage

Includes White Metal and 3D Printed parts. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale The Carriage

WP-903

O Scale Carriage Drive and Sawdust Blower

Includes White Metal and 3D Printed parts. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Carriage Drive and Sawdust Blower

WP-904

O Scale Live Rolls

Includes White Metal and 3D Printed parts. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Live Rolls

WP-905

O Scale Cut Off Saw and Dead Rolls

Includes White Metal, 3D Printed parts, and a laser cut sawblade. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Cut Off Saw and Dead Rolls

WP-907

O Scale Log Turner

Includes White Metal and 3D Printed parts, and scale brass chain. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Log Turner

WP-908

O Scale Log Deck

Includes White Metal and 3D Printed parts. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Log Deck

WP-909

O Scale Log Haul

Includes White Metal and 3D Printed parts, and scale brass chain. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale Log Haul

WP-910

O Scale The Edger

Includes White Metal, 3D Printed parts, and laser cut sawblades. Brass wire and stripwood not included and are required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs.

click here to view instructions for this kit

O Scale The Edger

WP-906

O Scale Line Shaft Kit

Includes White Metal and 3D Printed parts. Brass wire not included and is required to complete the kit. A list of these items are included. A link is provided in the kit to download detailed assembly instructions, drawings, and photographs. Information is included detailing the layout of the machinery as well as how to connect your line shaft to your mill engine and boiler.

click here to view instructions for this kit part one

click here to view instructions for this kit part two

O Scale Line Shaft Kit

click here to view sawmill machinery template pack

CHB Models

O Scale Sawmill Machinery Sets

Now Shipping

Save and Purchase an Entire Set

Sets Include a Printed Manual

O Scale Standard Sawmill Machinery Set

Kit WP-SET | Now Shipping

Contains all machines listed above

price listed does not include shipping and taxes

O Scale "Plus" Sawmill Machinery Set

Kit WP-SET-PLUS | Now Shipping

Everything Included in the Standard Sawmill Machinery Set plus the ME 900 Mill Engine and SB 850 Boiler

(pictured below)

price listed does not include shipping and taxes

CHB Models

O Scale Mill Engines and Boilers

Now Shipping

Kits include White Metal, Resin, and 3D Printed Details

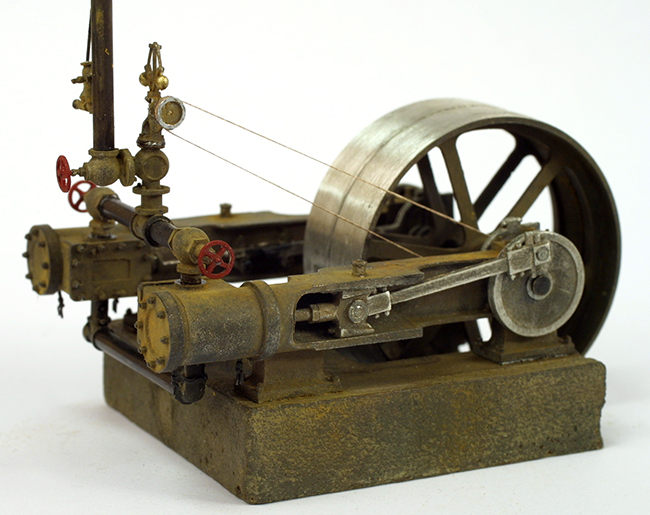

ME900

O Scale Double Cylinder Mill Engine

Paired with the Sawmill Machinery

O Scale Double Cylinder Mill Engine

Kit ME900 | Now Shipping

click here to view instructions for this kit

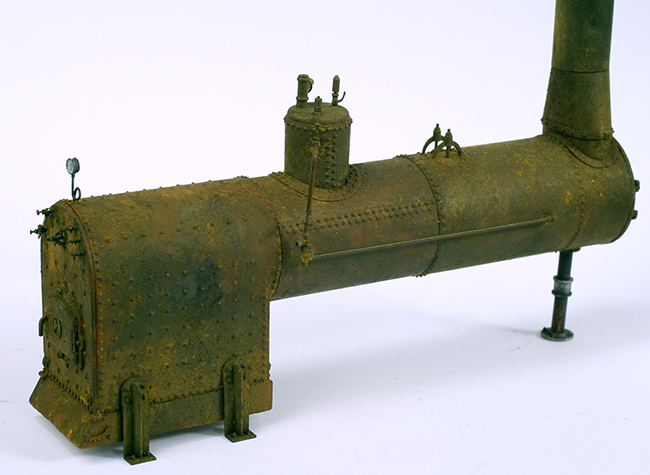

SB850

O Scale Horizontal Stationary Boiler

Paired with the Sawmill Machinery

O Scale Horizontal Stationary Boiler

Kit SB850 | Now Shipping