Diorama and Pilot Model Designed and Constructed by Brett Gallant

Special Thanks to Ken Karns for His Assistance

and a Hearty Nod of Appreciation to Bill Obenauf, Alan Hubbard, and Joel Freedman

Based Upon an Original Concept by Carlton Cornish

Names, Logos, Design, and Photographs Copyright Brett Gallant

the Award Winning

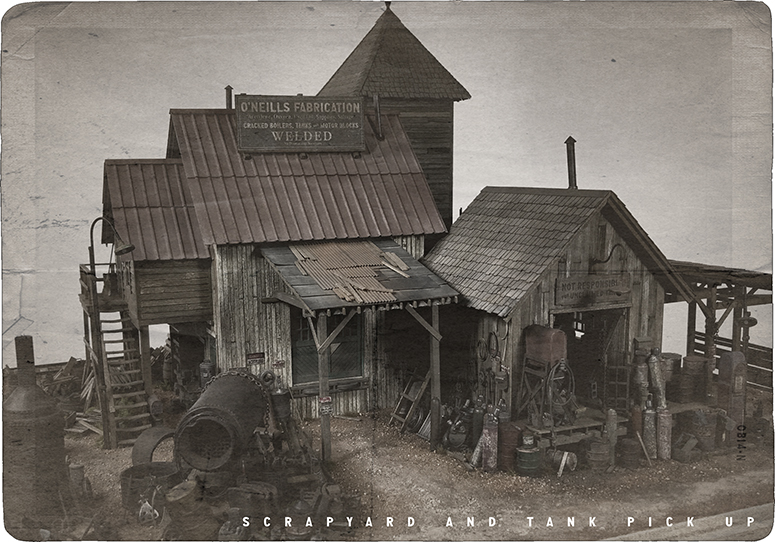

O Scale O'Neills Fabrication

A Tribute to My Friend Kevin O'Neill

1951-2013

Special Order Craftsman Kits 311a and 311b

O'Neills Fabrication diorama measures 15" x 16"

Updated with an Amazing Selection of 3D Printed Details!

Click Here for Information

On O'Neills Fabrication Part One

O'Neills Fabrication is a two-part kit and

both parts must be purchased

in order to complete the diorama

Click Here for Information

On O'Neills Fabrication Part Two

Click Here for the O'Neills Photo Album

O Scale O'Neills Fabrication Part One

Kit 311a | Special Order Reservation

$345 plus shipping and applicable taxes

A $50 Deposit is Due Now, Upon Checkout

Balance Due + Shipping Upon Shipment

Click the Buy Now button to pay your $50 Deposit.

Once your kit is ready, a balance due notice will be emailed.

Deposits are non-refundable.

Special Order Kit

What is a “Special Order” kit?

These are older kits that I do not make often. Instead of paying in full for this kit, you simply make a $50 non-refundable deposit with the balance due when your kit is ready to ship. If you would like to reserve this kit simply check out like normal and pay the $50 plus a small shipping fee. (This is a bookkeeping thing.) Once your kit is ready I will send an email with further instructions. Kits usually take about 90-120 days to ready for shipment. For more information on this specific kit please contact me prior to placing your reservation.

O Scale O'Neills Fabrication Part Two

Kit 311b | Special Order Reservation

$285 plus shipping and applicable taxes

A $50 Deposit is Due Now, Upon Checkout

Balance Due + Shipping Upon Shipment

Click the Buy Now button to pay your $50 Deposit.

Once your kit is ready, a balance due notice will be emailed.

Deposits are non-refundable.

Here are just a few of the features of SierraWest kits:

- Award Winning Board on Board Modeling Techniques -

- Learn My Techniques for Multiple Types of Wood Siding,

Masonry, Windows and Doors, and Roofing Materials -

- Large Assortment of New Castings and Realistic Clutter -

- Unique, Incredibly Fine Laser Made Details -

- Comprehensive Fully Illustrated Instructions -

- Thoughtful Time-Tested Techniques that You

Can Replicate to Advance your Skills and Confidence -

- Industry First Laser Cut Jigs and Assembly Aids -

- Intricate Laser Cut Windows, Doors, and Wall Framing -

- Signs Meticulously Researched and Reproduced

for Historical Accuracy and Time Period -

- Metal Roofing, Laser Cut Shingles, and Tarpapers -