Pilot Models Constructed by Brett Gallant

Names, Logos, Designs and Photographs Owned and Copyright Brett Gallant

the O Scale

Brass and Iron Foundry

Subscription Program

Already a Subscriber?

Part Three is Now Available to Order

New Subscriber?

A Few New Slots have been made Available

but... They Won't Last Long!

BIG and BOLD

the way SierraWest has brought it for 30 Years!

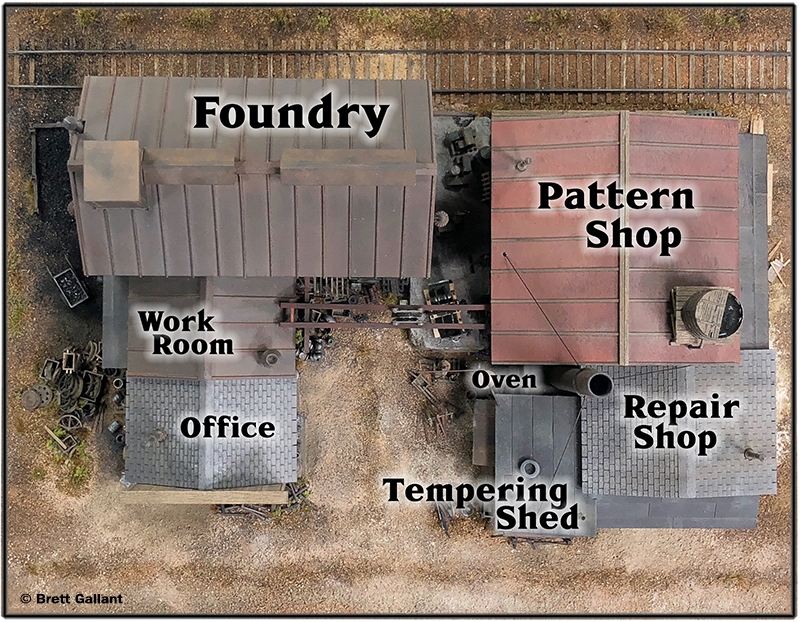

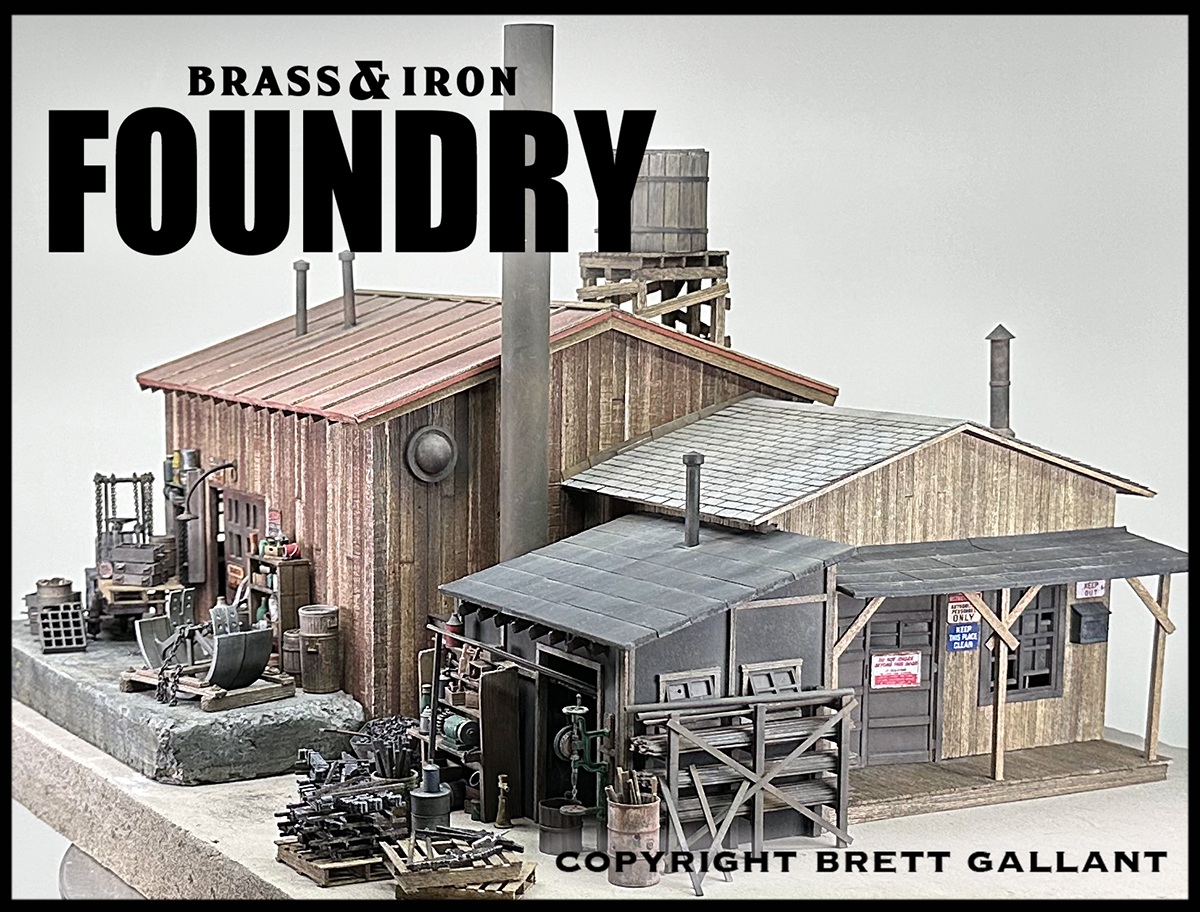

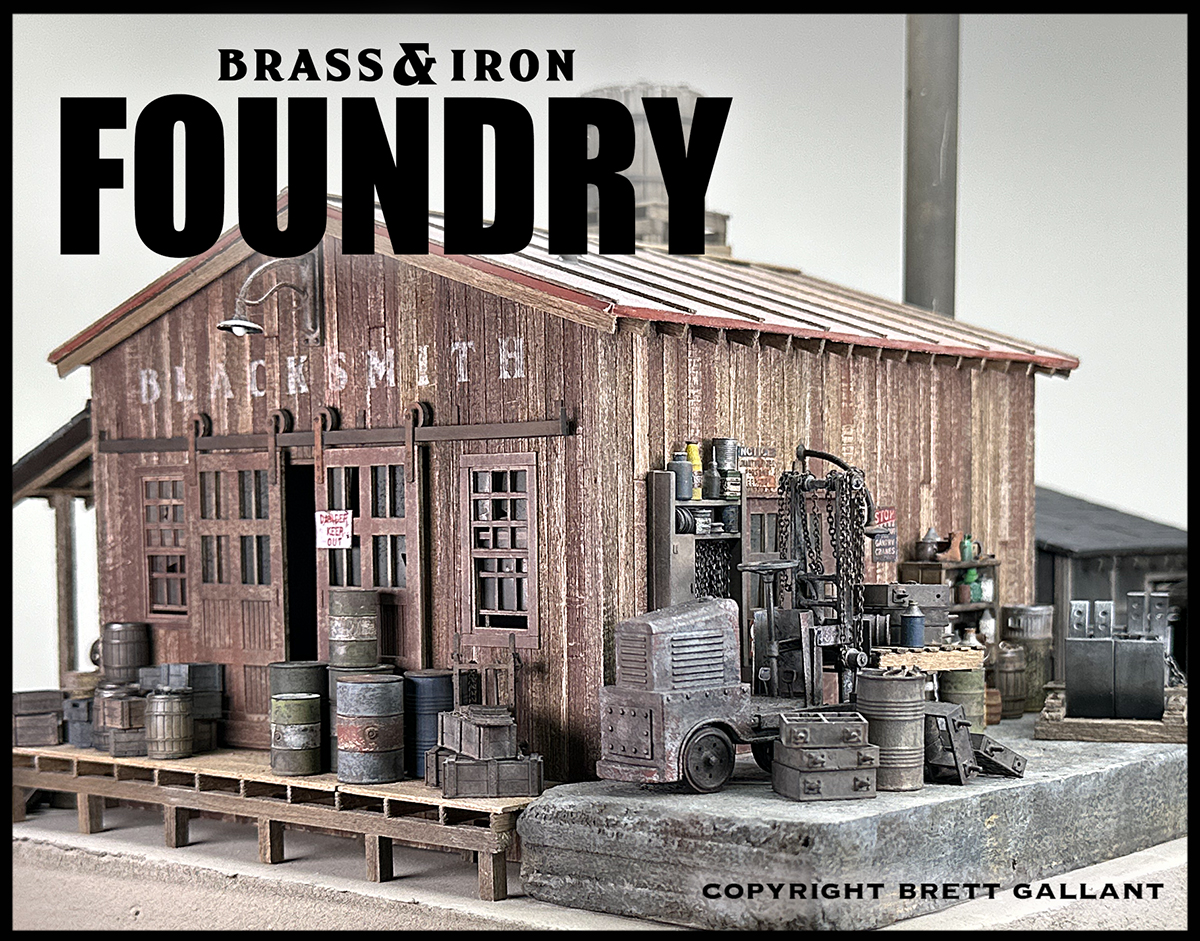

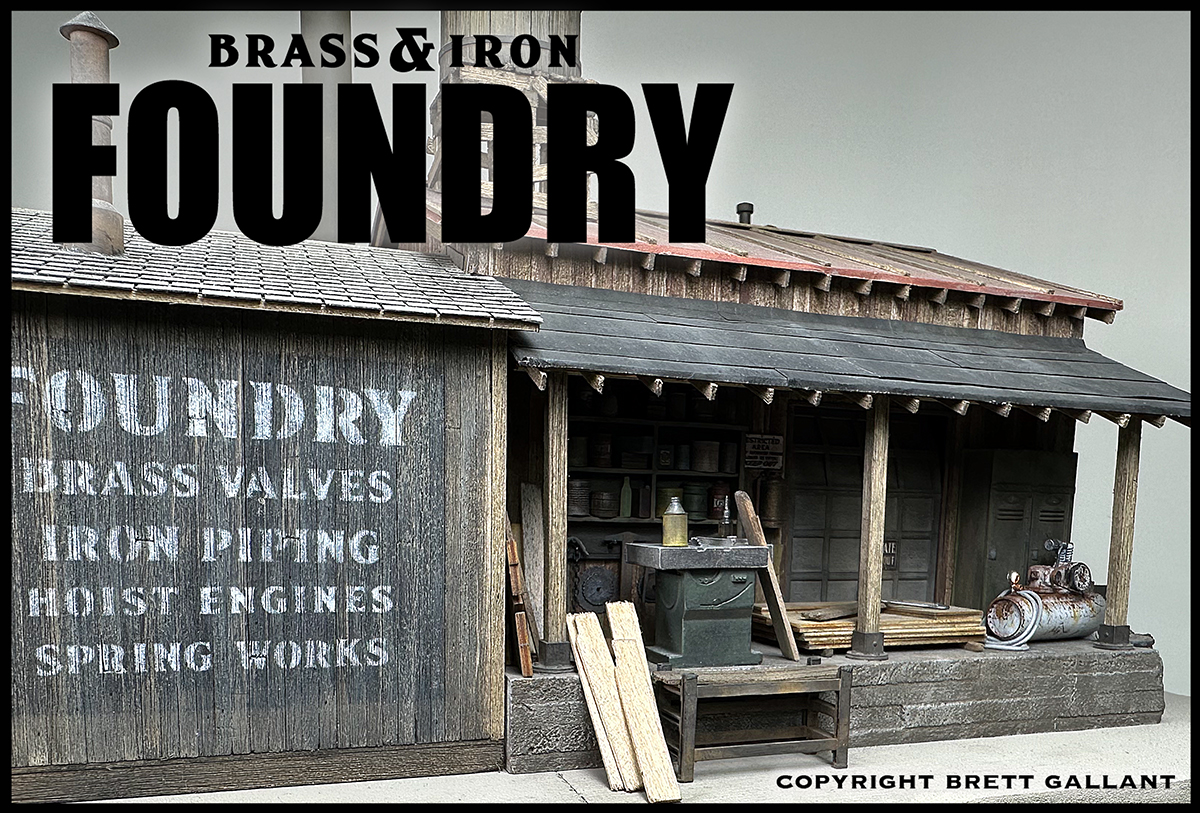

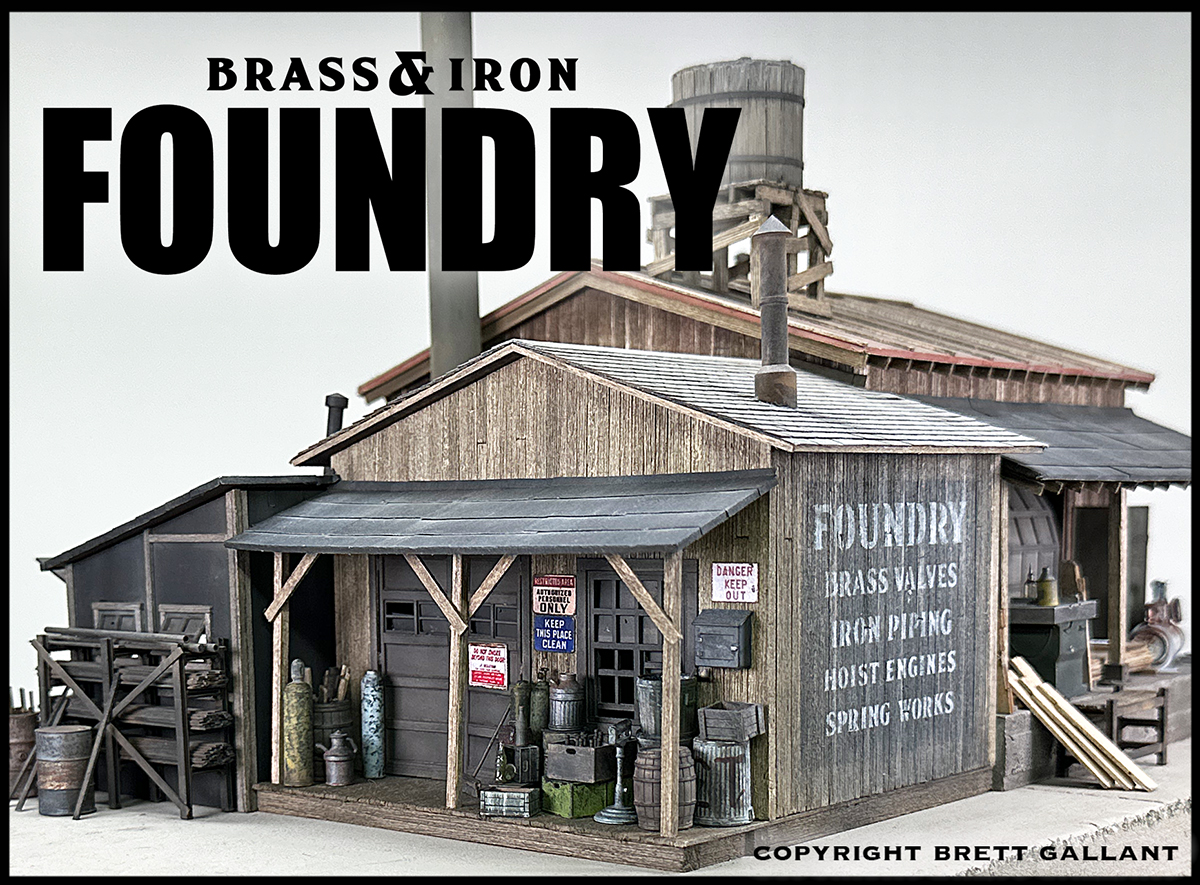

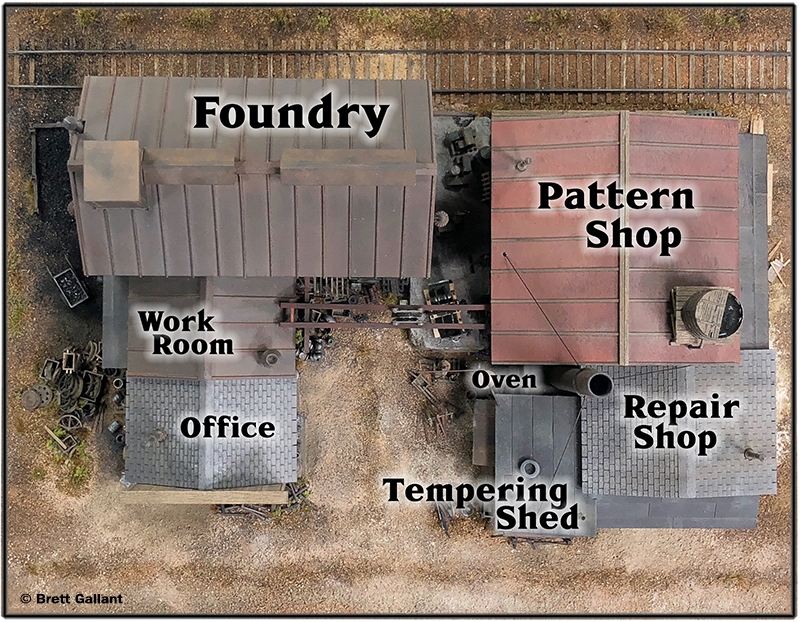

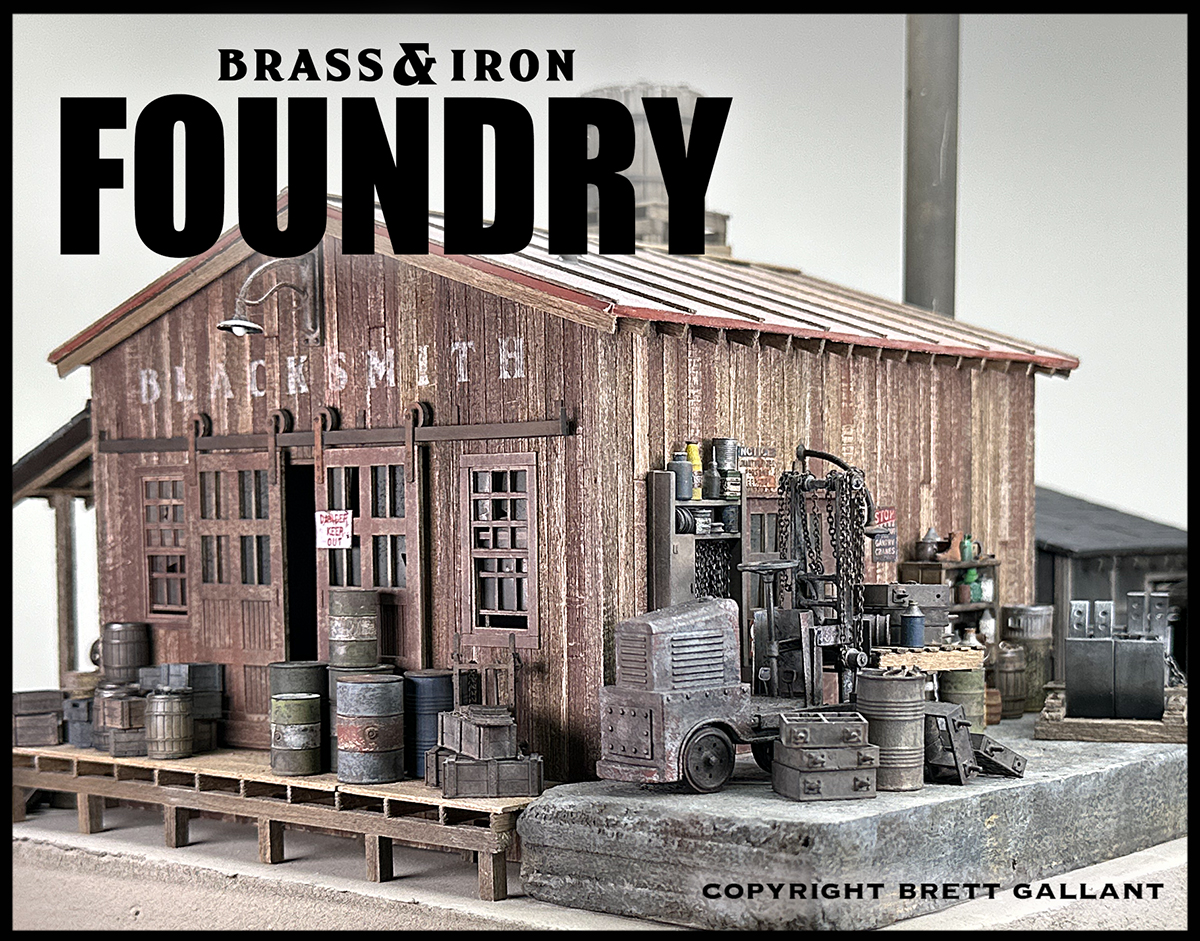

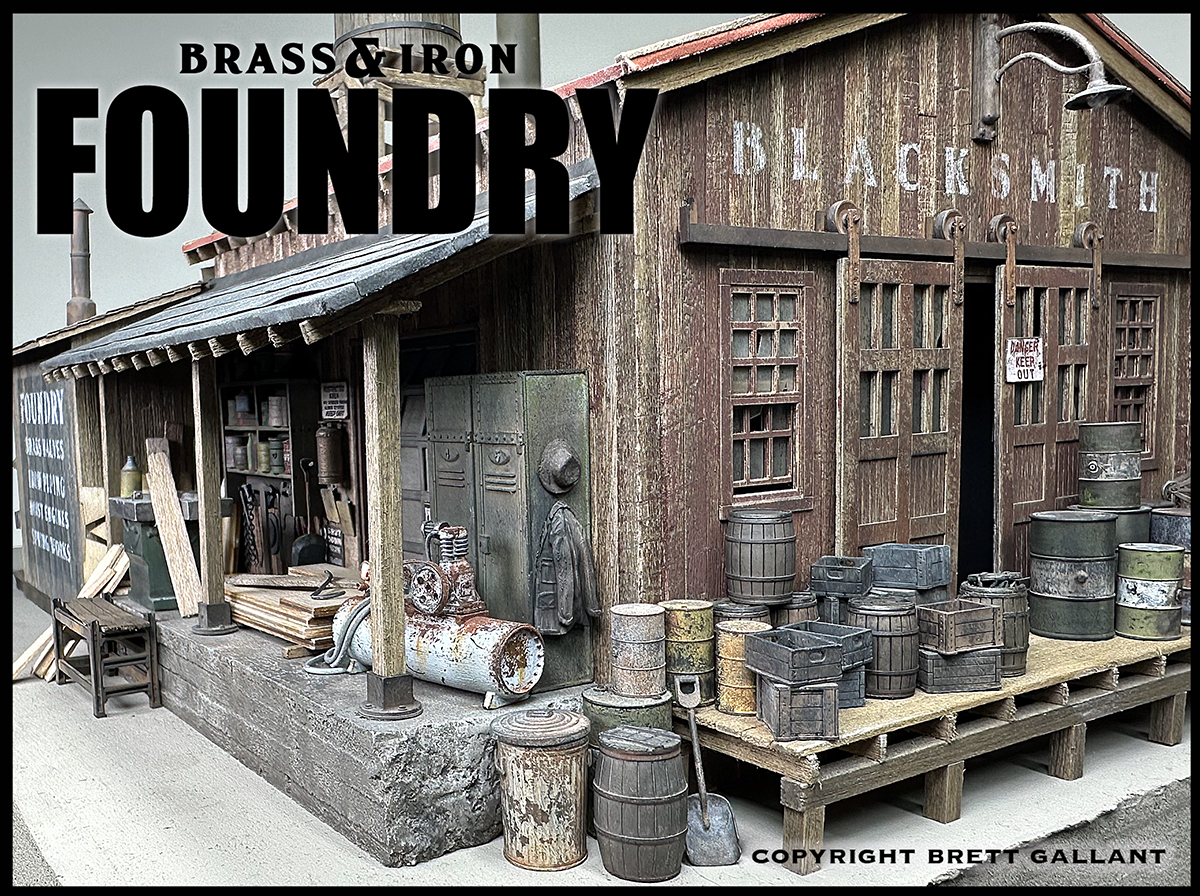

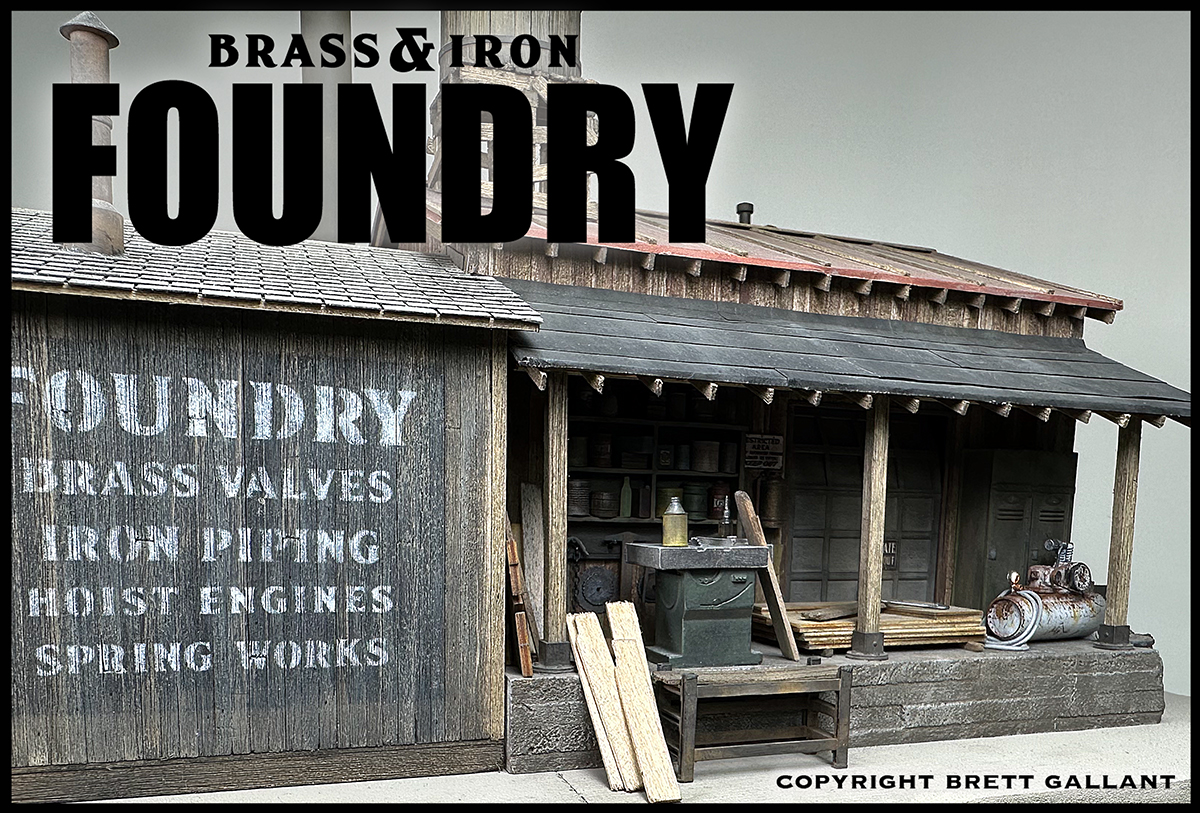

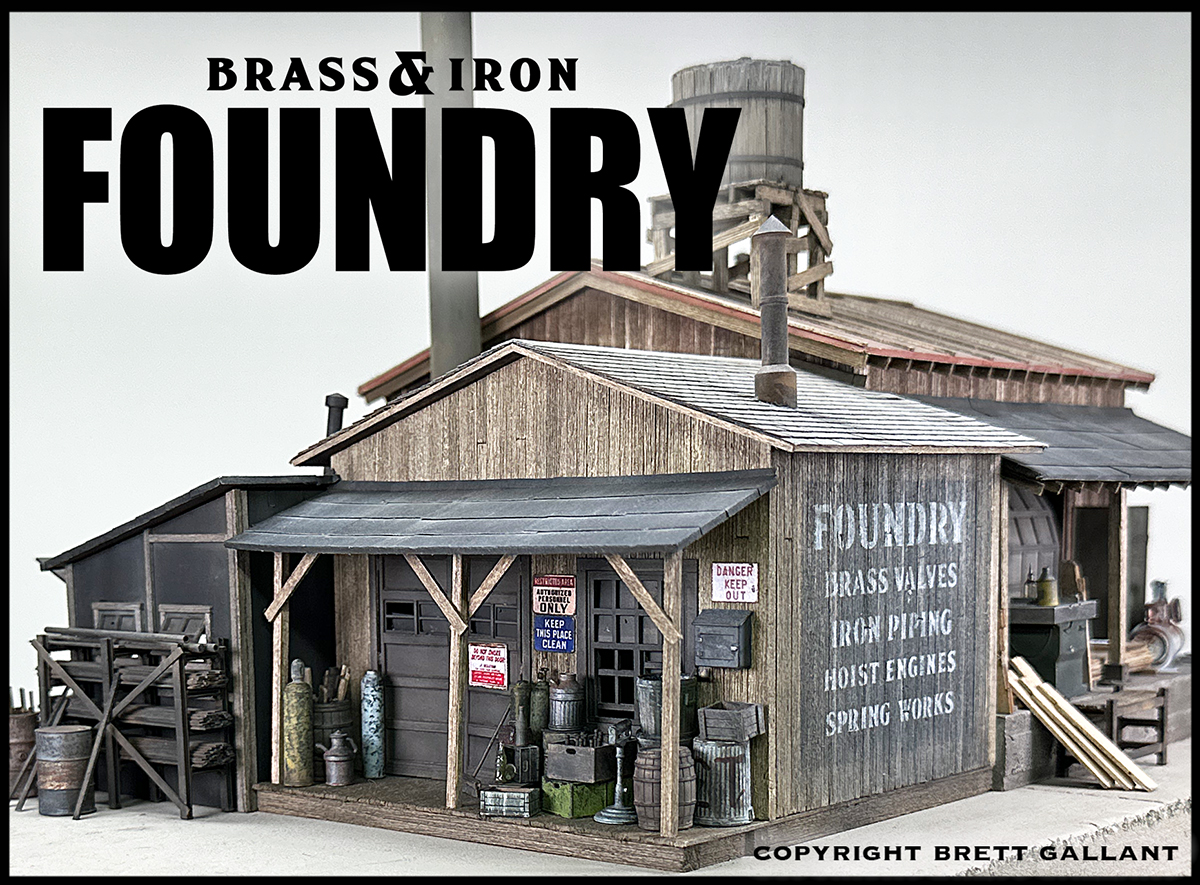

The photograph above is of the HO Scale Foundry. It is a thoughtfully researched multi-structure diorama with so many fascinating angles and scenes. The large stone main Foundry building anchors the diorama. Extending toward the front is a small stone materials preparation workroom and the company office. The clapboard office with its simple false front and recessed entry is a vintage scene that would have been so common anywhere in North America. The Pattern Shop anchors the right side of the diorama with the repair shop and incredible tempering oven/shed scene where truck springs were made in the early days of the automobile. Henry Ford would have been just one of the many characters seen wandering about the scene! The O Scale version is a faithful upscale of my award winning HO Scale diorama.

The photograph above is of the HO Scale Foundry. It is a thoughtfully researched multi-structure diorama with so many fascinating angles and scenes. The large stone main Foundry building anchors the diorama. Extending toward the front is a small stone materials preparation workroom and the company office. The clapboard office with its simple false front and recessed entry is a vintage scene that would have been so common anywhere in North America. The Pattern Shop anchors the right side of the diorama with the repair shop and incredible tempering oven/shed scene where truck springs were made in the early days of the automobile. Henry Ford would have been just one of the many characters seen wandering about the scene! The O Scale version is a faithful upscale of my award winning HO Scale diorama.  The third installment in the O Scale Brass and Iron Foundry subscription program features the detail set for the Spring Works along with the interior of the small Tempering Shed. The star of the show however is the large Main Loading Dock that ties the Stone Foundry Structure to the Pattern Shop. A few loose ends from the previous two releases are wrapped up here with the porch overhang for the the Pattern Shop carpentry dock and front work room included as well as the roof mounted water tank and large Tempering Oven stack. Follow along with the detailed photographs below to see all of these components.

The third installment in the O Scale Brass and Iron Foundry subscription program features the detail set for the Spring Works along with the interior of the small Tempering Shed. The star of the show however is the large Main Loading Dock that ties the Stone Foundry Structure to the Pattern Shop. A few loose ends from the previous two releases are wrapped up here with the porch overhang for the the Pattern Shop carpentry dock and front work room included as well as the roof mounted water tank and large Tempering Oven stack. Follow along with the detailed photographs below to see all of these components. Detail set 314c includes an amazing combination of brand new hand poured resin, 3D Printed, and traditional white metal castings. Having the capability to produce parts utilizing all three technologies provides the widest possible array of details. This is such a great opportunity for me to share unique castings with you tailor made for the situation. There are even new 55 gallon oil drums styles included. Why is this important? Subtle variation in even simple parts like an oil drum creates a more interesting scene. This meticulous approach is one of the foundations of my modeling philosophy. I love that bar stock rack. The three supports are 3D Printed as well as the bar stock clusters. The long bars are cut to size and then tempered in the shed to begin the leaf spring manufacturing process.

Detail set 314c includes an amazing combination of brand new hand poured resin, 3D Printed, and traditional white metal castings. Having the capability to produce parts utilizing all three technologies provides the widest possible array of details. This is such a great opportunity for me to share unique castings with you tailor made for the situation. There are even new 55 gallon oil drums styles included. Why is this important? Subtle variation in even simple parts like an oil drum creates a more interesting scene. This meticulous approach is one of the foundations of my modeling philosophy. I love that bar stock rack. The three supports are 3D Printed as well as the bar stock clusters. The long bars are cut to size and then tempered in the shed to begin the leaf spring manufacturing process.

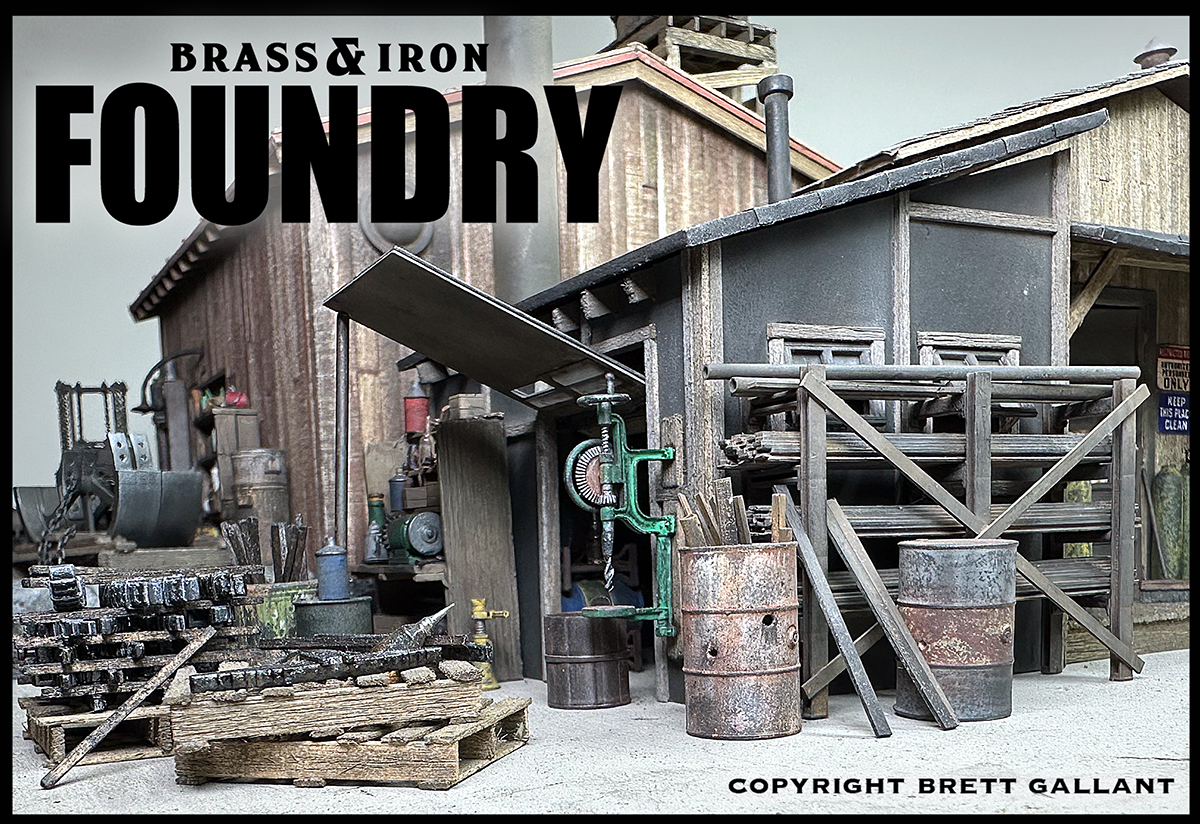

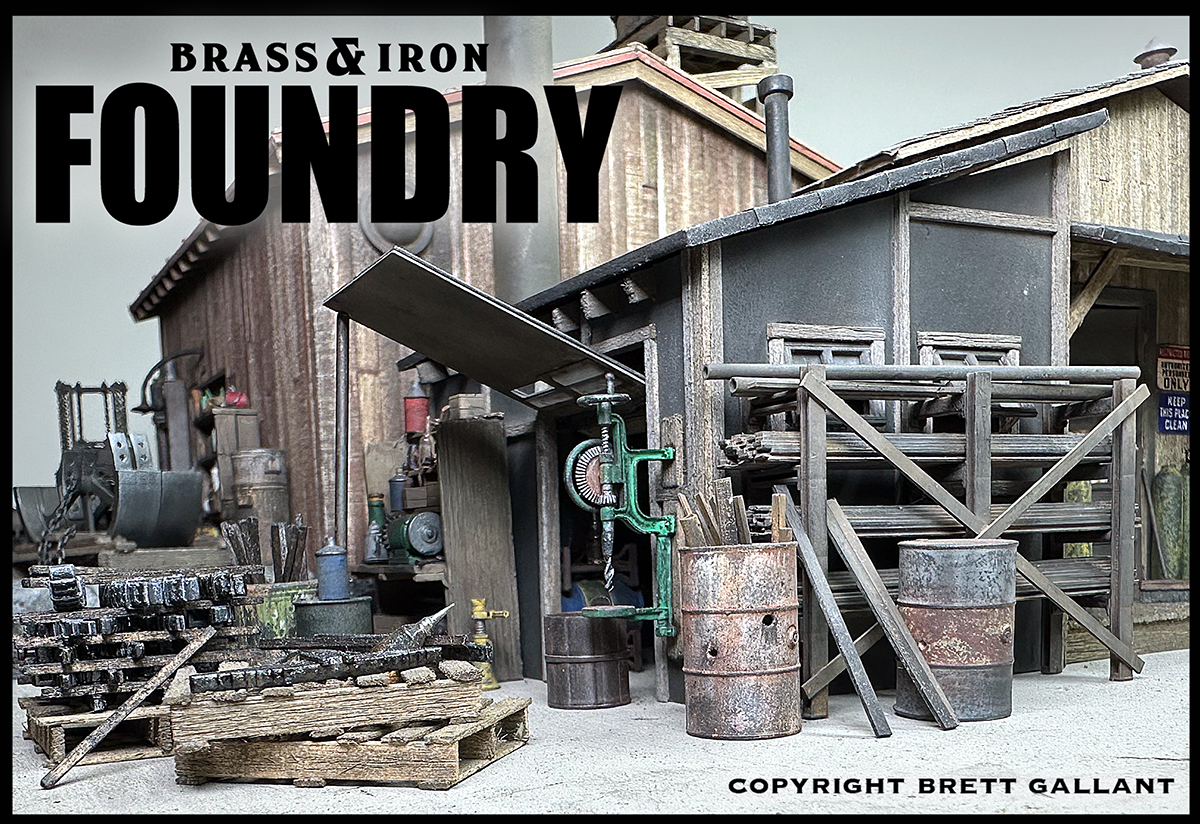

The exterior of the Spring Works features individual leaf springs in a variety of sizes and styles. These are stacked on palettes awaiting shipment. What a great storytelling scene based upon prototype photographs. Kinda grungy and oily from the manufacturing process. The scenery will be added as a final installment at the end of the series. This final release will include the large overhead crane and small details that will be used around the various structures to reinforce and support the different scenes.

The exterior of the Spring Works features individual leaf springs in a variety of sizes and styles. These are stacked on palettes awaiting shipment. What a great storytelling scene based upon prototype photographs. Kinda grungy and oily from the manufacturing process. The scenery will be added as a final installment at the end of the series. This final release will include the large overhead crane and small details that will be used around the various structures to reinforce and support the different scenes.

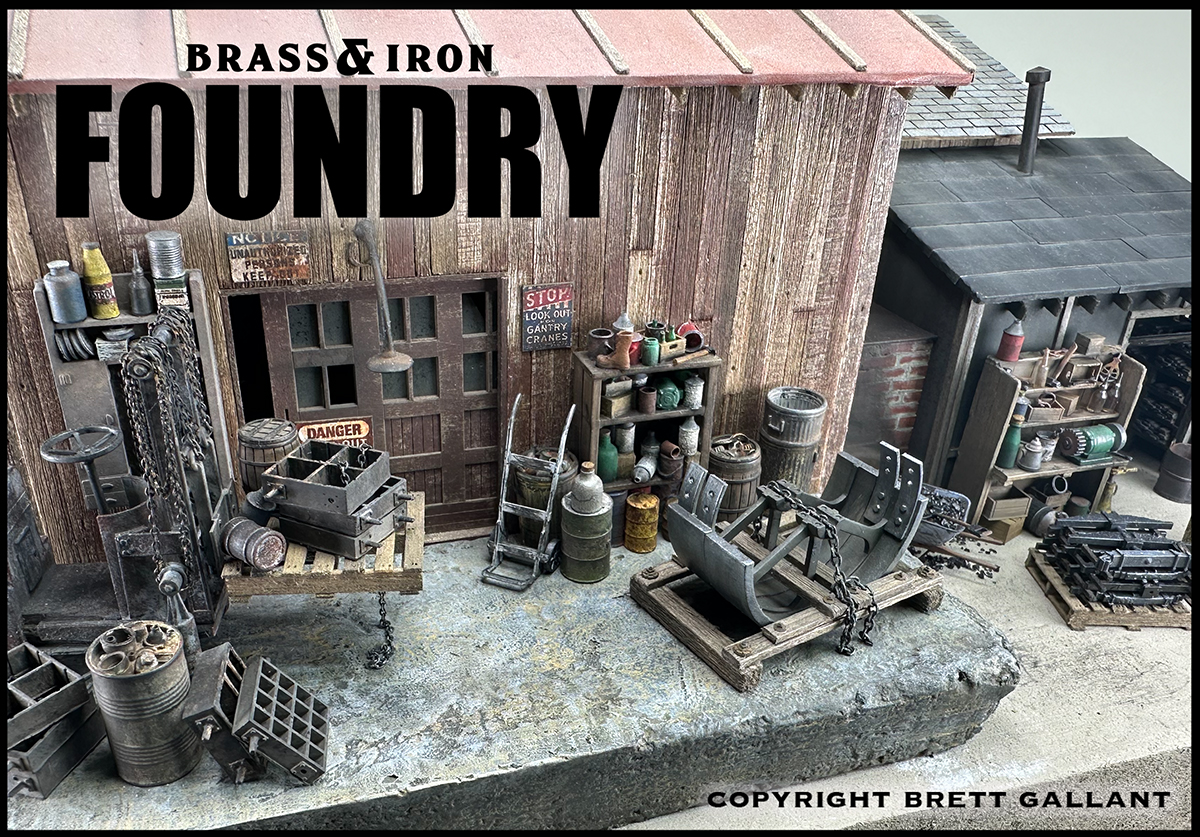

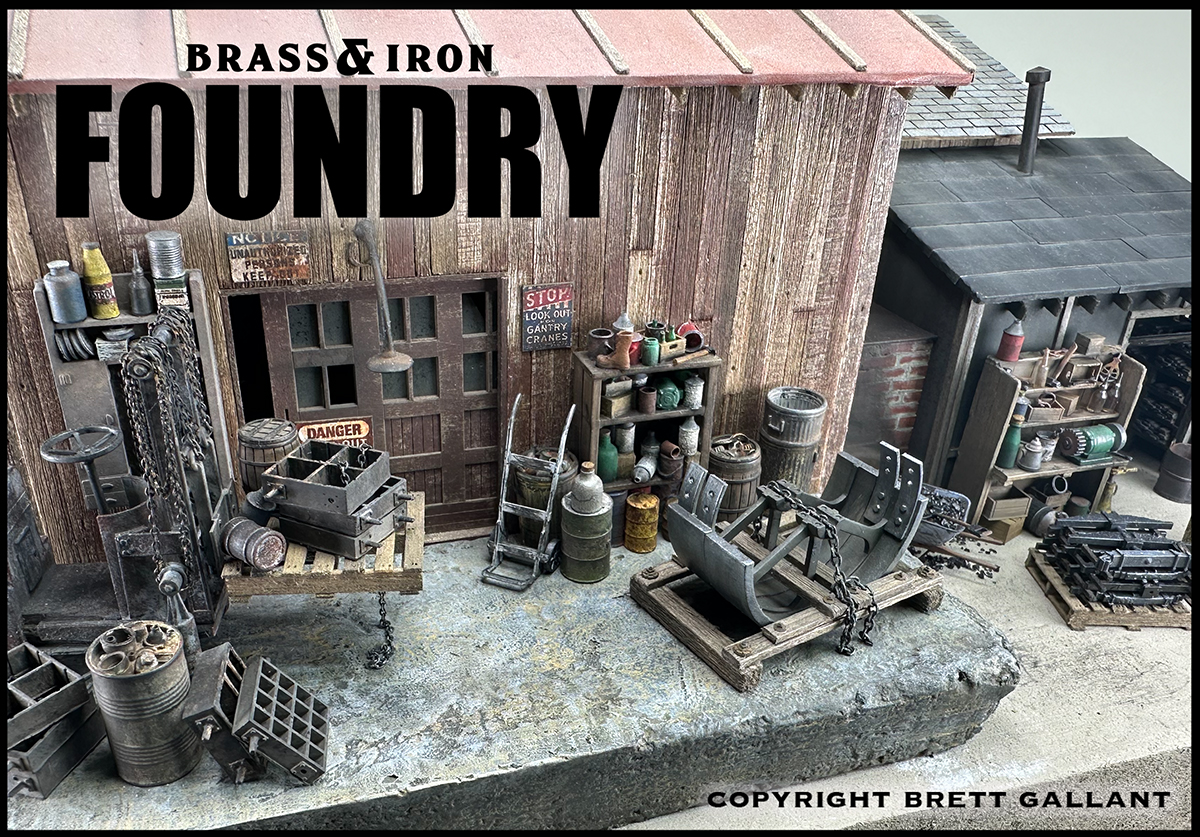

Now we can start discussing that large concrete dock! The dock itself is a hand poured resin casting and has so much character, texture, and detail. Hands down my favorite loading dock scene I have created. That's one of the reasons I wanted to offer this kit in a subscription format as it provides me more freedom to produce scenes that would not have been possible in a single release kit. There is so much happening here. Make sure to zoom in and take it all in. The large split driven wheel would have been a specialty of the foundry and shipped in halves as shown. You will notice the various mold boxes with the different configured dividers and handles. These are stacked upon one another to create the "cells" that the production pattern was placed in. Then sand was packed around the pattern and eventually the metal poured in creating the casting. The mold boxes on this dock are just the beginning of the foundry story telling. Much more to come with the next releases.

Now we can start discussing that large concrete dock! The dock itself is a hand poured resin casting and has so much character, texture, and detail. Hands down my favorite loading dock scene I have created. That's one of the reasons I wanted to offer this kit in a subscription format as it provides me more freedom to produce scenes that would not have been possible in a single release kit. There is so much happening here. Make sure to zoom in and take it all in. The large split driven wheel would have been a specialty of the foundry and shipped in halves as shown. You will notice the various mold boxes with the different configured dividers and handles. These are stacked upon one another to create the "cells" that the production pattern was placed in. Then sand was packed around the pattern and eventually the metal poured in creating the casting. The mold boxes on this dock are just the beginning of the foundry story telling. Much more to come with the next releases.

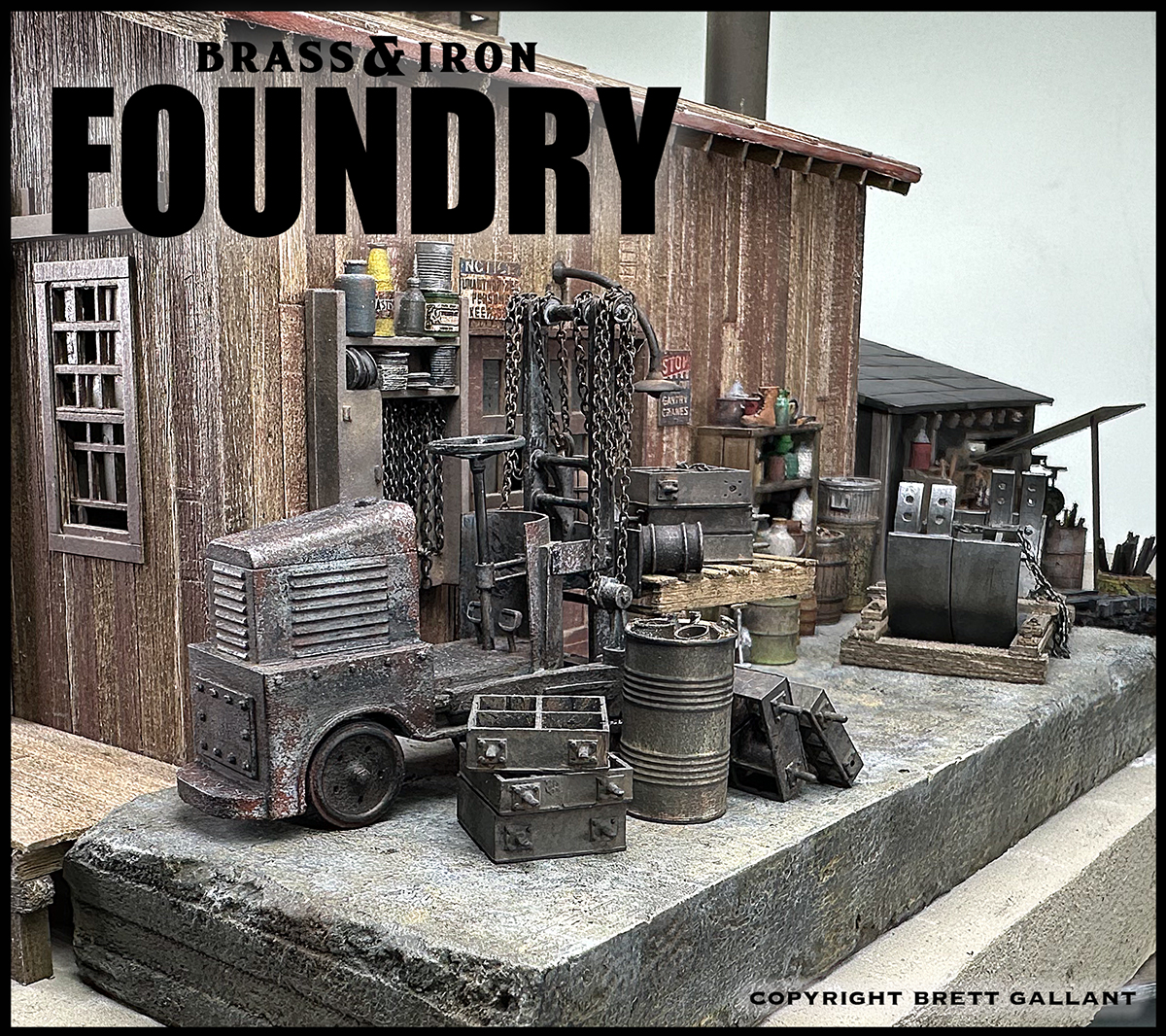

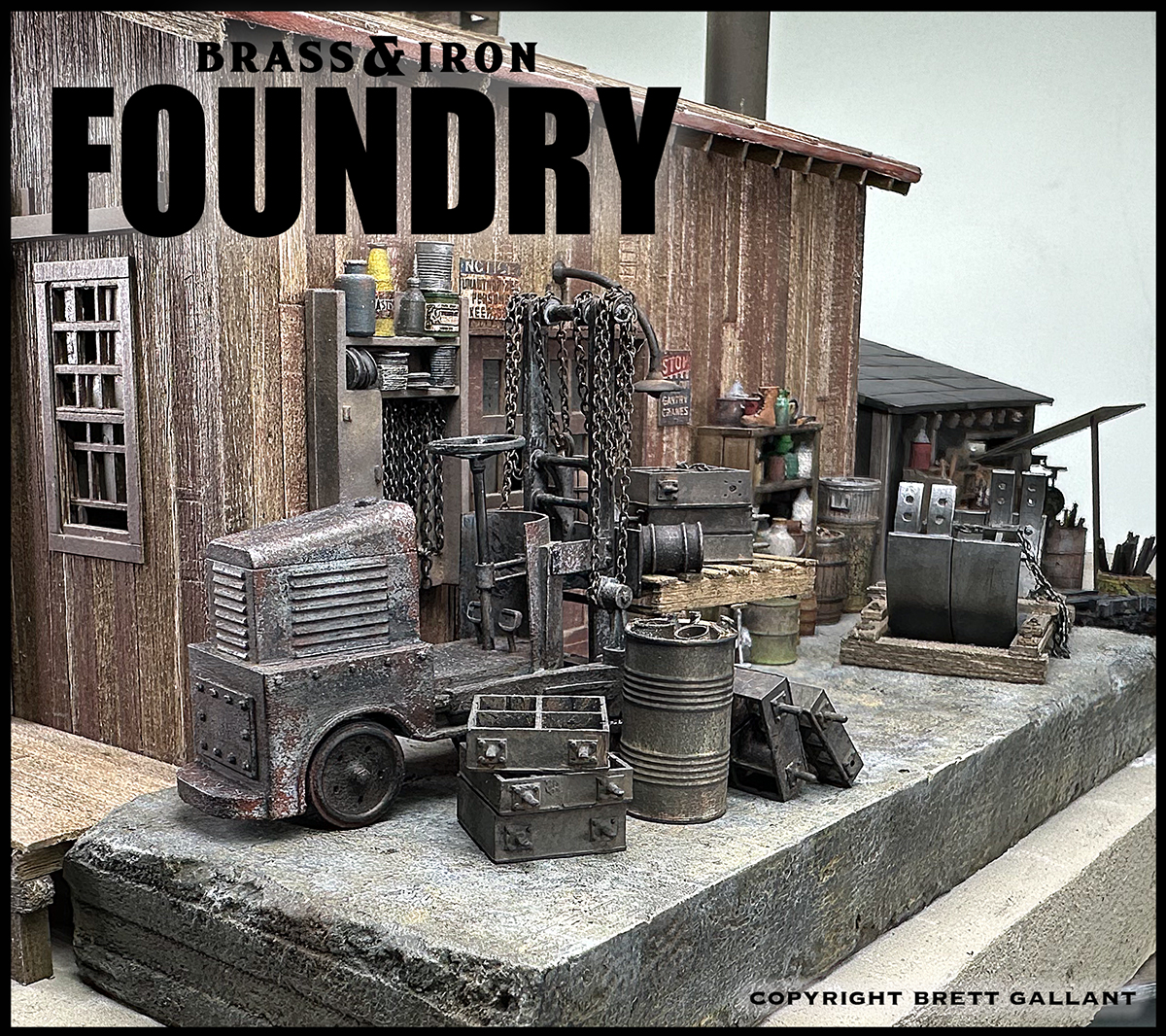

Without question my favorite detail is the vintage forklift. It is a heavily modified version of the 1924 Duat tractor with forks. The Duat was the first internal combustion forklift and truly revolutionized warehouses. For the first time, they could take advantage of vertical space by double-stacking loads. There’s nothing better for me than bringing historical accuracy to my kits. I had an absolute blast with this kit. A couple thoughts: The chain was made from iron links back then so the rusty appearance is exactly prototypical. You will notice the forklift tower is too tall to fit thru the doorway in the background. The piece is designed to fit in a doorway on the opposite side of the dock not pictured that enters the stone foundry. This is a pre-production model and while yours will appear exactly the same, I re-made the flanges on the pulleys a bit deeper so the chain would fit between them better. A subtle but important change. I loved the way this one weathered up so I decided to use it instead of modeling a second one.

Without question my favorite detail is the vintage forklift. It is a heavily modified version of the 1924 Duat tractor with forks. The Duat was the first internal combustion forklift and truly revolutionized warehouses. For the first time, they could take advantage of vertical space by double-stacking loads. There’s nothing better for me than bringing historical accuracy to my kits. I had an absolute blast with this kit. A couple thoughts: The chain was made from iron links back then so the rusty appearance is exactly prototypical. You will notice the forklift tower is too tall to fit thru the doorway in the background. The piece is designed to fit in a doorway on the opposite side of the dock not pictured that enters the stone foundry. This is a pre-production model and while yours will appear exactly the same, I re-made the flanges on the pulleys a bit deeper so the chain would fit between them better. A subtle but important change. I loved the way this one weathered up so I decided to use it instead of modeling a second one.

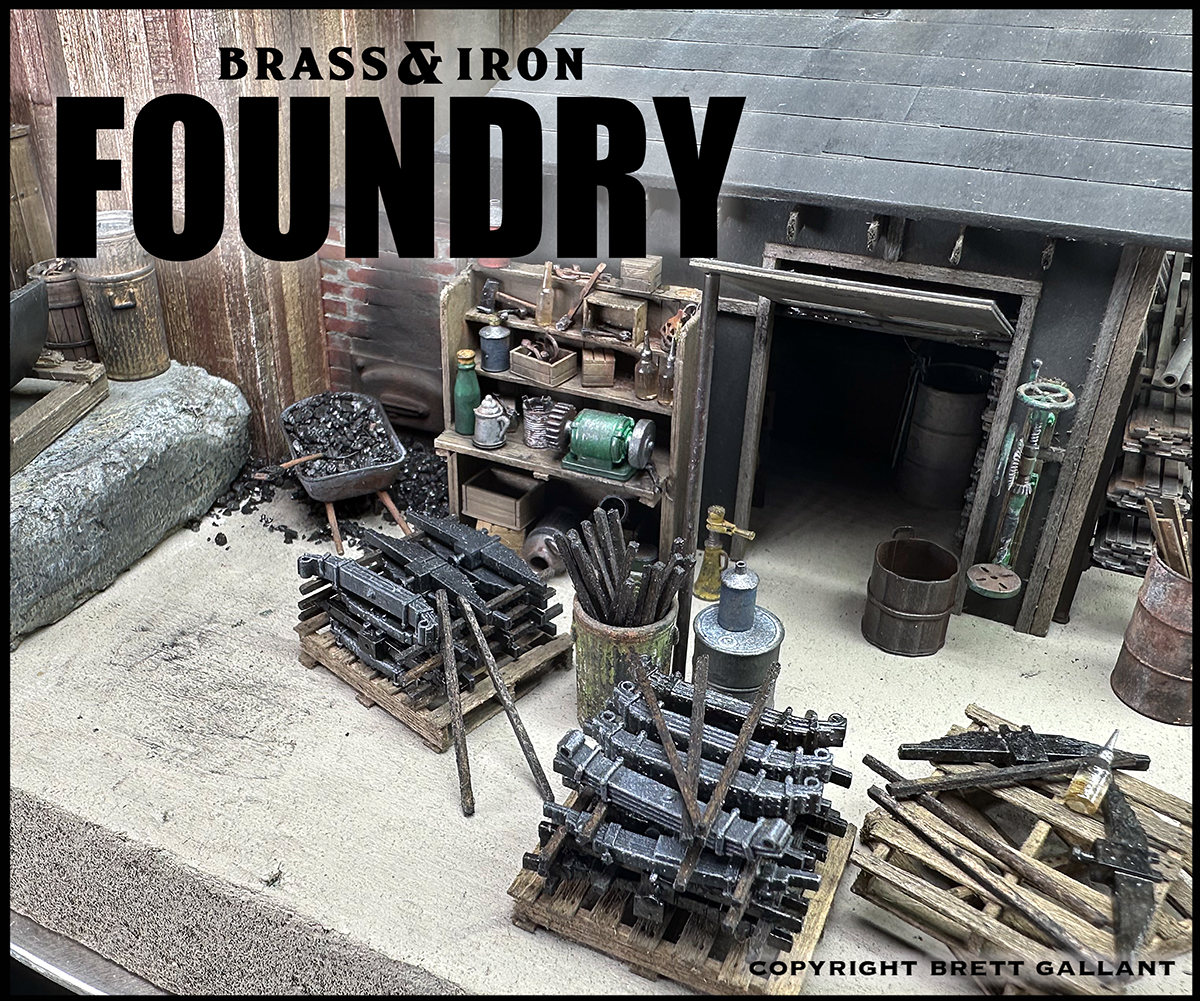

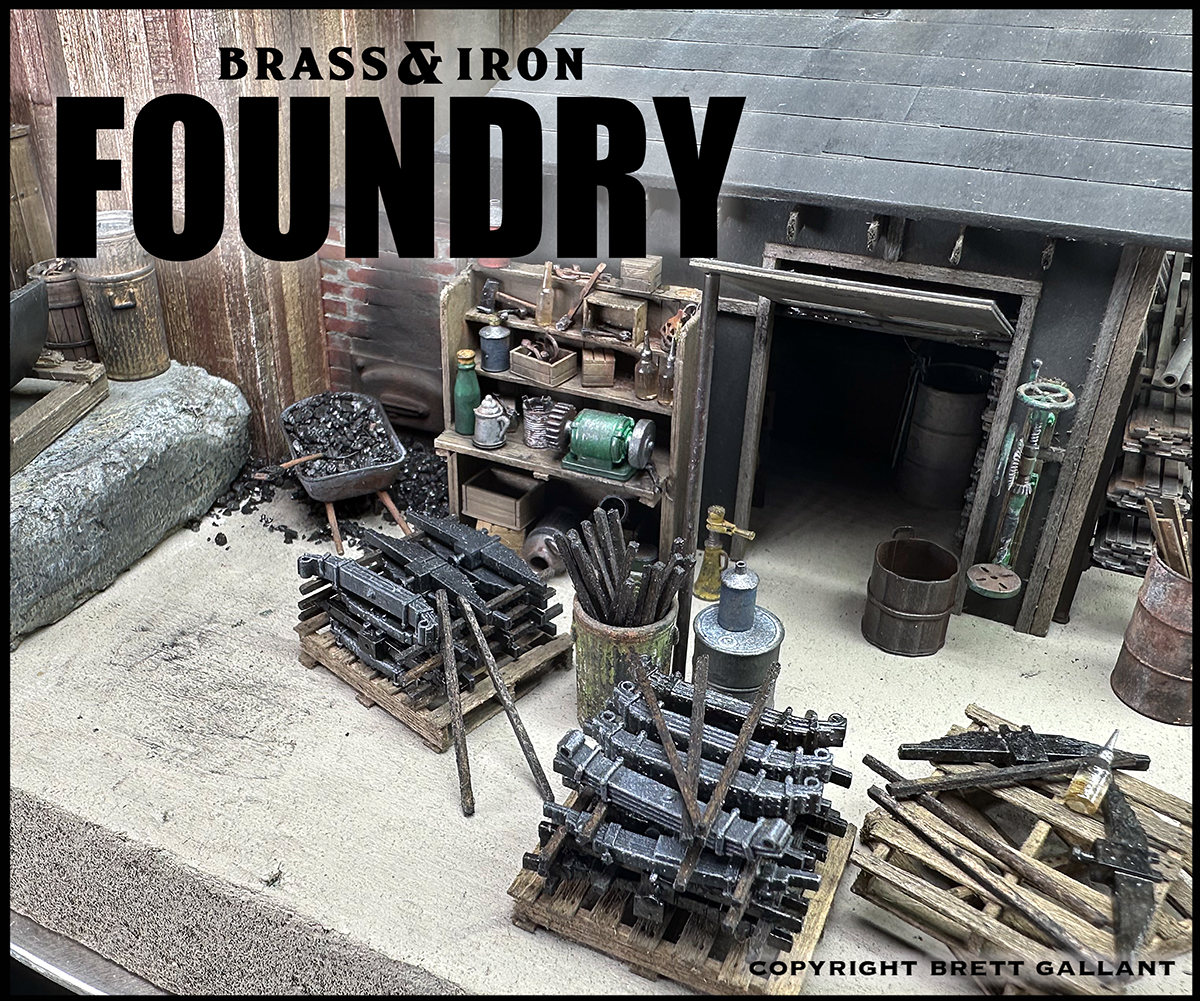

These trio of photographs provide a view of the details included inside the Tempering Shed. I love telling stories with the scenes created in my dioramas. The Tempering Shed story ties the whole right hand side of the foundry diorama together. The forge inside the shed was the original forge used by the blacksmith whose stenciled name appears over the rear doorway. The forge was relocated when the structure was repurposed into the foundries pattern shop. The large tempering oven provides the heat for the forge and you can see the interior brick wall that connects them together. When the scenery is installed, an asbestos wrapped pipe will transfer heat from the oven to the forge. I pulled my two favorite shed details out for a better shot. Both are 3D Printed and exemplify the diverse way that I can tailor create details for a specific location and story. The 30 gallon oil drum rack is comprised of separate drums and rack components. In contrast, the small stock support is a single piece. The long bar stock outside is cut to create the leaf springs and once cut, stored on the smaller rack.

These trio of photographs provide a view of the details included inside the Tempering Shed. I love telling stories with the scenes created in my dioramas. The Tempering Shed story ties the whole right hand side of the foundry diorama together. The forge inside the shed was the original forge used by the blacksmith whose stenciled name appears over the rear doorway. The forge was relocated when the structure was repurposed into the foundries pattern shop. The large tempering oven provides the heat for the forge and you can see the interior brick wall that connects them together. When the scenery is installed, an asbestos wrapped pipe will transfer heat from the oven to the forge. I pulled my two favorite shed details out for a better shot. Both are 3D Printed and exemplify the diverse way that I can tailor create details for a specific location and story. The 30 gallon oil drum rack is comprised of separate drums and rack components. In contrast, the small stock support is a single piece. The long bar stock outside is cut to create the leaf springs and once cut, stored on the smaller rack.

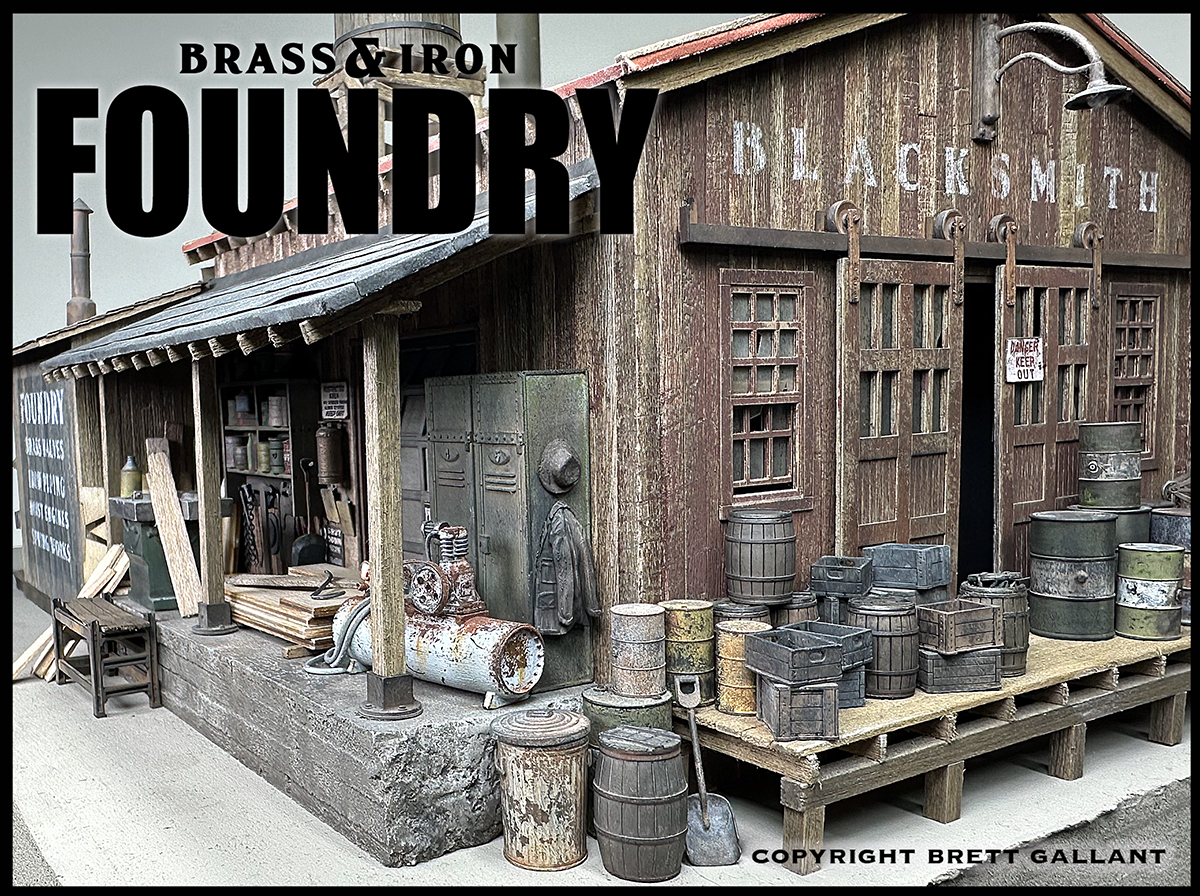

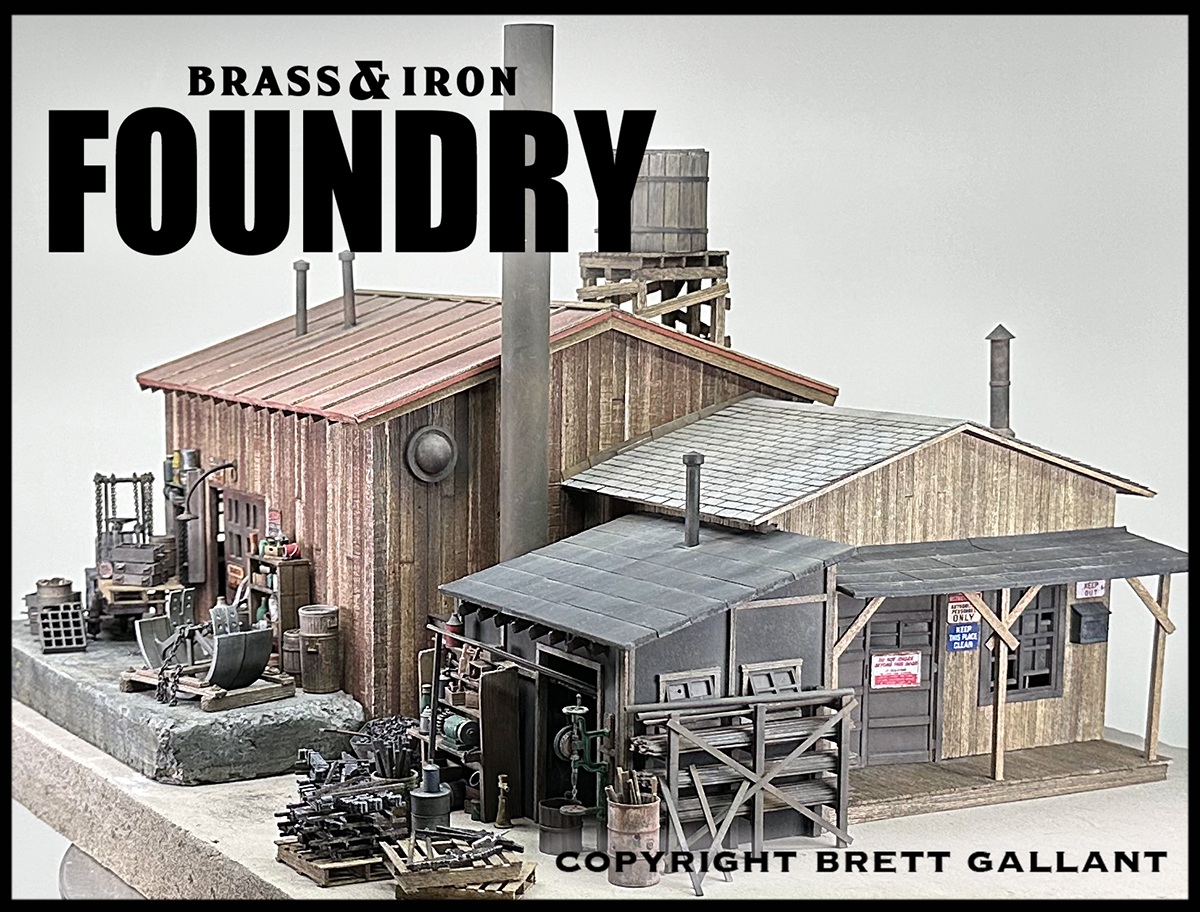

The following photographs provide views of the diorama with all three installments pictured together. I can't decide which scene I love more. Each turn of the diorama reveals a level of detail simply unimaginable even a few years ago! The rear dock includes drums filled with casting oil and kerosene as well as wooden barrels filled with nails. Those long crates are filled with brass casting ingots for the foundry oven. The open crate and straw packing material is right at home and something I have always wanted to include in a kit. I am not sure there's really even enough room to walk around on the small dock!

The following photographs provide views of the diorama with all three installments pictured together. I can't decide which scene I love more. Each turn of the diorama reveals a level of detail simply unimaginable even a few years ago! The rear dock includes drums filled with casting oil and kerosene as well as wooden barrels filled with nails. Those long crates are filled with brass casting ingots for the foundry oven. The open crate and straw packing material is right at home and something I have always wanted to include in a kit. I am not sure there's really even enough room to walk around on the small dock!

All the different materials, textures, and colors create such an interesting scene. Lots to take in here and exemplifies how versatile the various materials and weathering techniques are. Is it a shame to place the dock covering over all that fine detail? No worries, it is removable! My single favorite detail in this scene has to be the early electric air compressor. The level of detail on this beast is only to be appreciated in person. This one was weathered by Karl Allison and is amazing. Be sure to zoom in and check out all that beautiful rust. I love the table saw scene with the small scaffolding placed for the operator to stand upon. The perfect reinforcement to a repurposed blacksmith shop. The scenery will include lots of sawdust.

All the different materials, textures, and colors create such an interesting scene. Lots to take in here and exemplifies how versatile the various materials and weathering techniques are. Is it a shame to place the dock covering over all that fine detail? No worries, it is removable! My single favorite detail in this scene has to be the early electric air compressor. The level of detail on this beast is only to be appreciated in person. This one was weathered by Karl Allison and is amazing. Be sure to zoom in and check out all that beautiful rust. I love the table saw scene with the small scaffolding placed for the operator to stand upon. The perfect reinforcement to a repurposed blacksmith shop. The scenery will include lots of sawdust.

Brass and Iron Foundry Part Three

314c - The third installment in the O Scale Brass and Iron Foundry subscription program features the detail set for the Spring Works along with the interior of the small Tempering Shed. The star of the show however is the large Main Loading Dock and all of its amazing details. A few loose ends from the previous two releases are wrapped up here with the porch overhang for the the Pattern Shop carpentry dock and front work room included as well as the roof mounted water tank and large Tempering Oven stack.

O Scale Brass and Iron Foundry Part Three

Kit 314c | Now Shipping

$240 plus shipping and applicable taxes

Only Current Subscribers May Order!

Contact me BEFORE ordering Part Three if you have not purchased the previous releases directly from me.

O Scale Brass and Iron Foundry Part One

Kit 314a | Pattern Shop

Repair Shop

Tempering Shed

O Scale Brass and Iron Foundry Part Two

314b - Exterior Detail Sets for:

Rear Loading Dock

Pattern Shop Dock

Front Repair Shop

Future Releases:

Brass and Iron Foundry

315a

Office and Workroom with details

315b

Stone Foundry with details

315c

Gantry Crane and Yard details