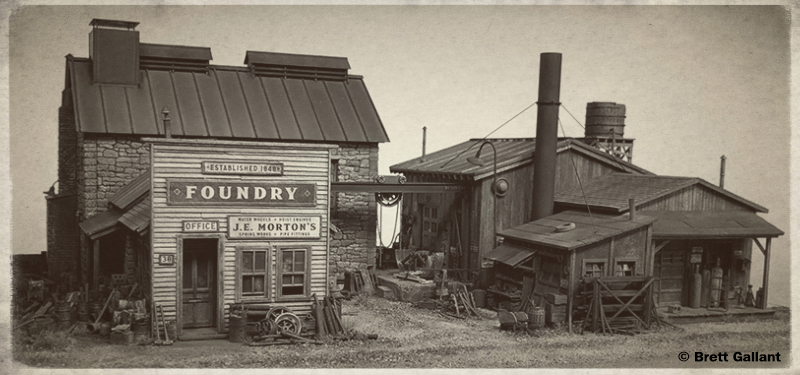

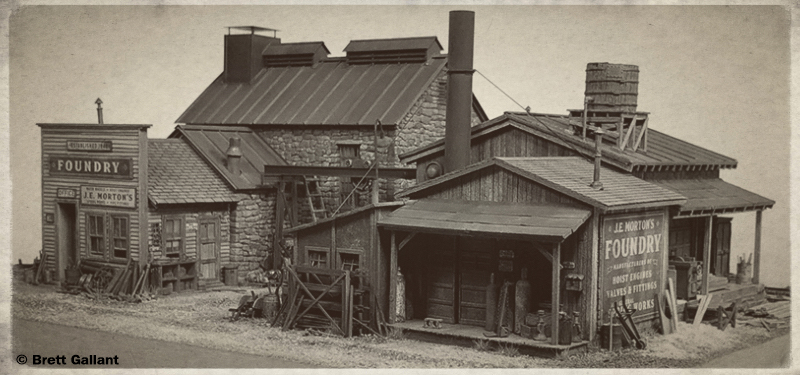

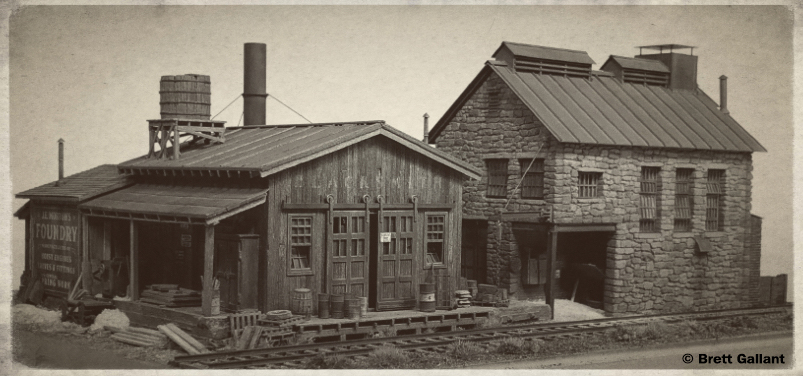

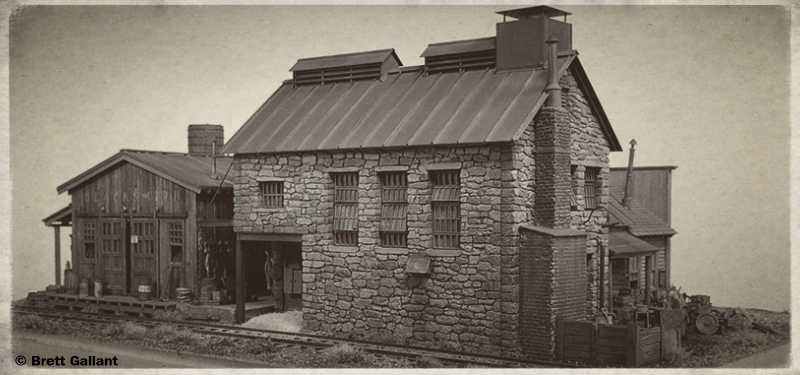

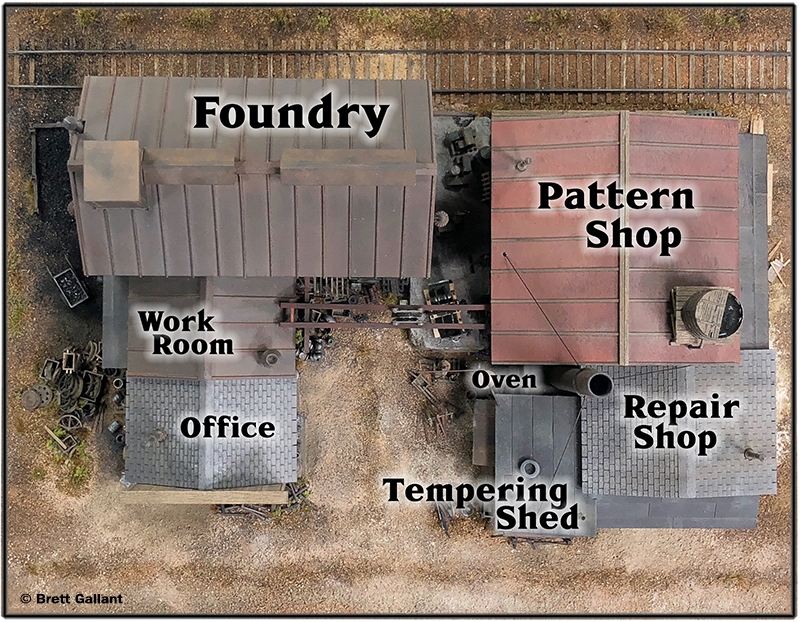

Diorama and Pilot Model Designed and Constructed by Brett Gallant

A Very Special Thanks to Brian Marriott for Techical Expertise

Names, Logos, Designs and Photographs Owned and Copyright Brett Gallant

HO Scale Brass and Iron Foundry

The Foundry is the companion to O'Neills Fabrication

Limited Edition Craftsman Kit Number 212

Updated with an Amazing Selection of 3D Printed Details!

Click Here for Detailed Photographs and to Learn

More about Morton's Brass and Iron Foundy

Click Here for the Morton's Vintage Photo Album

HO Scale Brass and Iron Foundry

Kit 212 | Now Shipping

Everything Pictured is Included Except Track and Senery

The Diorama Measures Approximately 11" x 14"

Price does not include shipping and applicable taxes

First Time Ordering?

click here to learn about lead times and policies

The attention to the smallest detail is evident. The story telling is paramount in the development of each new kit. Instructions are provided leading you through every phase of construction including tool selection, assembly, weathering and aging, diorama composition, and scenery creation and application. It is of the utmost of importance to me that the techniques I develop and utilize are reproducible for modelers of all experience levels. When you view the pictures of Morton's remember this. SierraWest kits are unique in the level and amount of detail provided. Since all four sides are fully detailed, you have a ton of flexibility in placement and view-ability.

Here are just a few of the features of SierraWest kits:

- Award Winning Board on Board Modeling Techniques -

- Learn My Techniques for Multiple Types of Wood Siding,

Masonry, Windows and Doors, and Roofing Materials -

- Large Assortment of New Castings and Realistic Clutter -

- Unique, Incredibly Fine Laser Made Details -

- Comprehensive Fully Illustrated Instructions -

- Thoughtful Time-Tested Techniques that You

Can Replicate to Advance your Skills and Confidence -

- Industry First Laser Cut Jigs and Assembly Aids -

- Intricate Laser Cut Windows, Doors, and Wall Framing -

- Signs Meticulously Researched and Reproduced

for Historical Accuracy and Time Period -

- Metal Roofing, Laser Cut Shingles, and Tarpapers -