Diorama and Pilot Model Designed and Constructed by Brett Gallant

A Very Special Thanks to Brian Marriott for Techical Expertise

Names, Logos, Designs and Photographs Owned and Copyright Brett Gallant

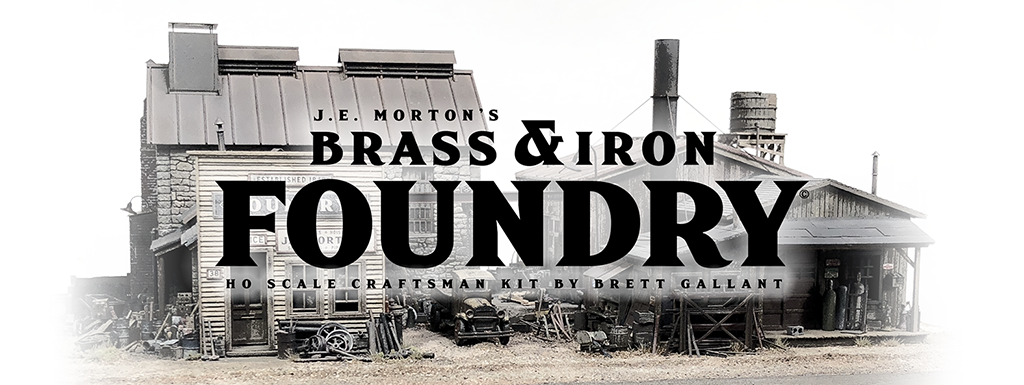

HO Sale Brass and Iron Foundry

The Foundry is the companion to O'Neills Fabrication

Limited Edition Craftsman Kit Number 212

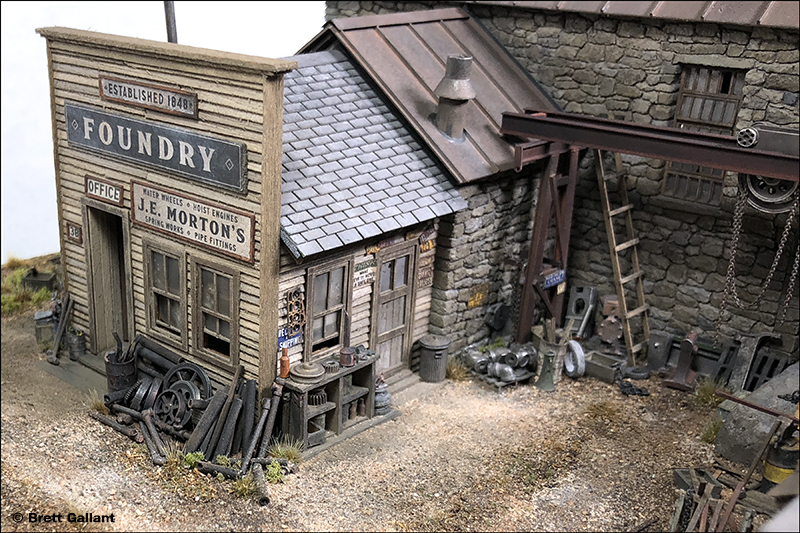

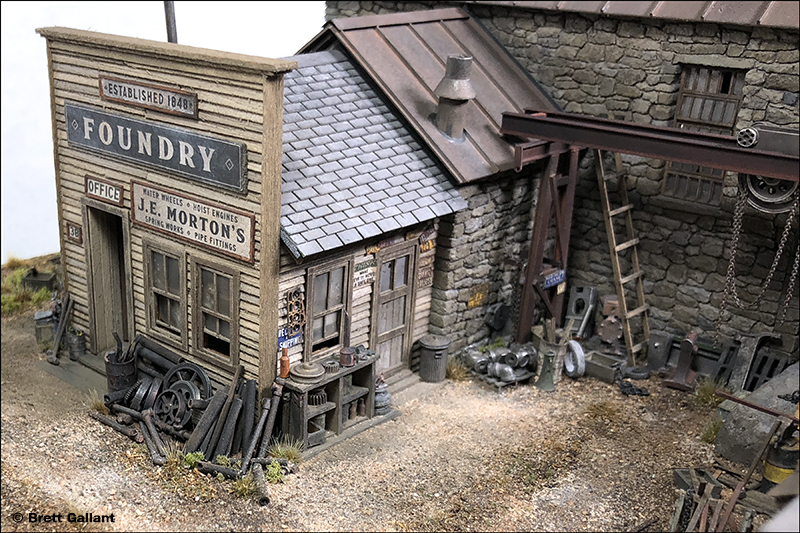

The main yard features various foundry castings awaiting shipment tucked under the gantry crane. The clutter is so realistic in its appearance that it is difficult to remember this is HO Scale and the diorama is only 11 x 14 inches. As you study the following photographs notice the realistic coloring and weathering. This is all created with water based paints, artist chalk, and rubbing alcohol. My techniques have been used all over the the world by many award winning modelers and I am so proud of their results. My manual guides you through the assembly and weathering process in unrivaled detail. The diorama is rich in signs and details cluttering the walls. Notice the vintage license plates and old engine gaskets hanging on the office.

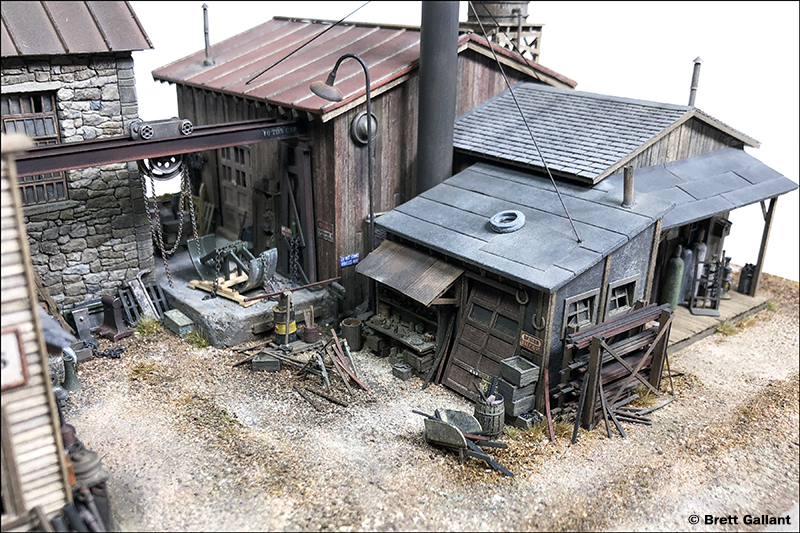

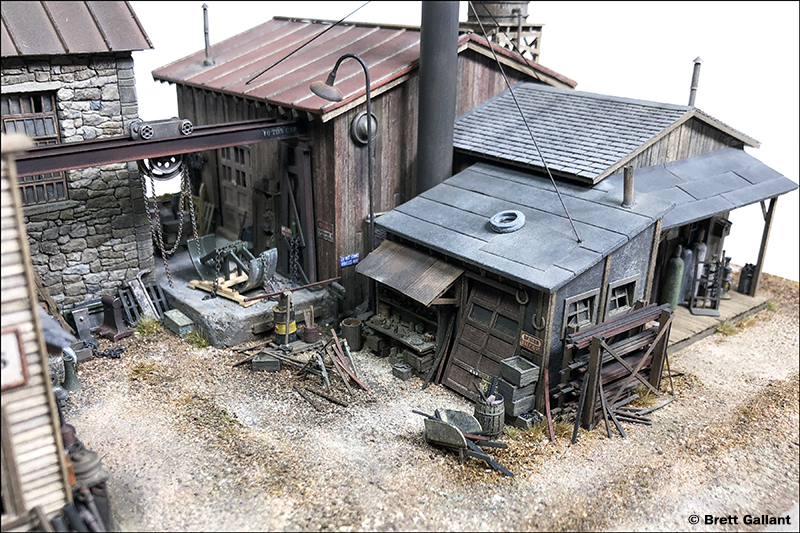

The main yard features various foundry castings awaiting shipment tucked under the gantry crane. The clutter is so realistic in its appearance that it is difficult to remember this is HO Scale and the diorama is only 11 x 14 inches. As you study the following photographs notice the realistic coloring and weathering. This is all created with water based paints, artist chalk, and rubbing alcohol. My techniques have been used all over the the world by many award winning modelers and I am so proud of their results. My manual guides you through the assembly and weathering process in unrivaled detail. The diorama is rich in signs and details cluttering the walls. Notice the vintage license plates and old engine gaskets hanging on the office. Here is a great view of the spring works tempering shed and the associated detail and clutter. The wheel barrow and bar stock support rack are wonderful examples of my laser cut details. SierraWest kits are very unique in that I combine resin and metal castings with cutting edge laser technology. This creates a scene of uncompromising detail, texture, and variety that in addition provides for a fantastic building experience. Note the vise mounted on the black and yellow oil drum with the bar stock clamped between it and the stock support. The two-wheel differential hoist and I-beam gantry crane is a prototypically engineered detail that would be used to load foundry castings on trucks parked underneath.

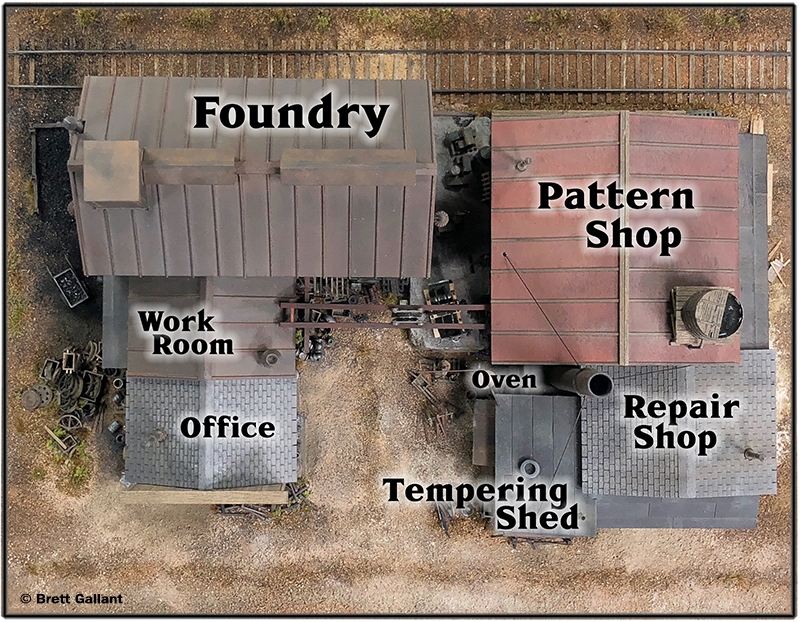

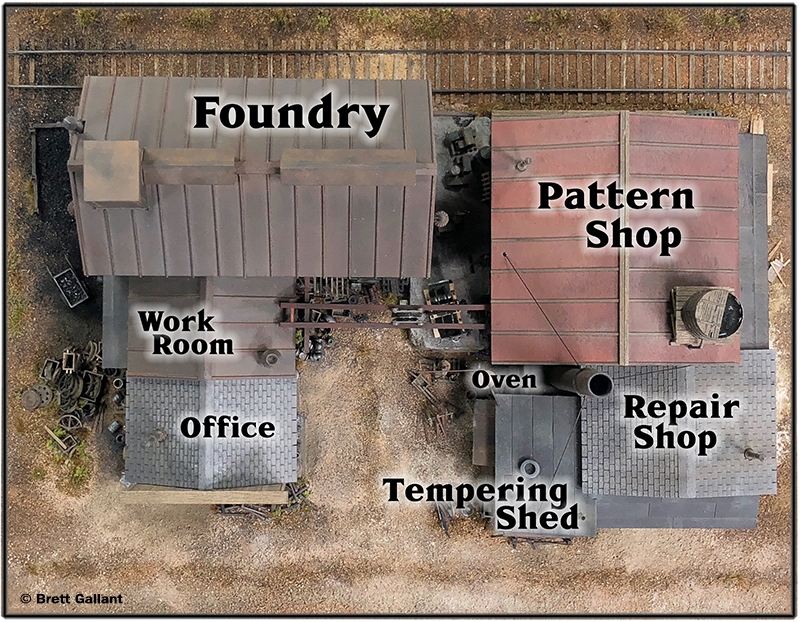

Here is a great view of the spring works tempering shed and the associated detail and clutter. The wheel barrow and bar stock support rack are wonderful examples of my laser cut details. SierraWest kits are very unique in that I combine resin and metal castings with cutting edge laser technology. This creates a scene of uncompromising detail, texture, and variety that in addition provides for a fantastic building experience. Note the vise mounted on the black and yellow oil drum with the bar stock clamped between it and the stock support. The two-wheel differential hoist and I-beam gantry crane is a prototypically engineered detail that would be used to load foundry castings on trucks parked underneath. This overhead view gives you a great perspective of the main foundry yard. The various roofing materials are very realistic and interesting. I love the standing seam roofing on the foundry and workroom. It has such great dimension and coloring. My famous comprehensive manual and digitally reproduced accurate templates guide you thoughtfully along the construction process. I consider myself a teacher in addition to being a manufacturer. My manual provides guidance and confidence building techniques allowing you to reproduce the results pictured here. I am so proud of the number of customers who have won major national awards with the SierraWest kits they have constructed by following the provided instructions!

This overhead view gives you a great perspective of the main foundry yard. The various roofing materials are very realistic and interesting. I love the standing seam roofing on the foundry and workroom. It has such great dimension and coloring. My famous comprehensive manual and digitally reproduced accurate templates guide you thoughtfully along the construction process. I consider myself a teacher in addition to being a manufacturer. My manual provides guidance and confidence building techniques allowing you to reproduce the results pictured here. I am so proud of the number of customers who have won major national awards with the SierraWest kits they have constructed by following the provided instructions! A construction shot taken prior to the installation of the foundry lets us see the dock details. I just love the four wheel loading dock cart with the crates of brass ingots stacked on its decking. My favorite however is the large mill engine wheel halves being prepared for shipment, rigged and then hoisted up by the gantry crane for loading. This is such a great scene nestled between the two structures. Peering between the buildings reveals all this great story telling.

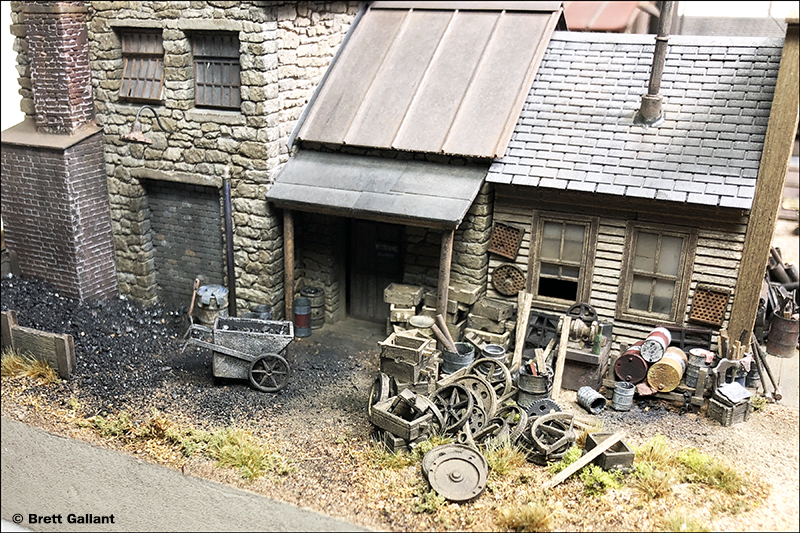

A construction shot taken prior to the installation of the foundry lets us see the dock details. I just love the four wheel loading dock cart with the crates of brass ingots stacked on its decking. My favorite however is the large mill engine wheel halves being prepared for shipment, rigged and then hoisted up by the gantry crane for loading. This is such a great scene nestled between the two structures. Peering between the buildings reveals all this great story telling. The light duty repair shop handles on-site maintenance of the machinery and equipment. The gas bottles and screw jacks support this effort. I am never satisfied to sit back and use the same techniques and castings from kit to kit, year after year. I am always looking for better ways to weather, new castings to enhance the diorama, and better scenery materials. This adds interest and provides all of us with a unique learning experience that never gets boring or stale. I am so proud that my kits are always evolving and improving!

The light duty repair shop handles on-site maintenance of the machinery and equipment. The gas bottles and screw jacks support this effort. I am never satisfied to sit back and use the same techniques and castings from kit to kit, year after year. I am always looking for better ways to weather, new castings to enhance the diorama, and better scenery materials. This adds interest and provides all of us with a unique learning experience that never gets boring or stale. I am so proud that my kits are always evolving and improving! Removing the canopy roof on the pattern shop concrete dock reveals a fantastic scene. The table saw is used to cut the sides for the mold boxes which are then assembled for use in the casting process. The lumber stacked on the dock is consumed in the creation of the all important wood patterns. The patterns are the very foundation of the casting process. These patterns are stored for many years in the shop and are protected from fire by the roof mounted water tank. Looking closely at the dock, you will see plywood sheets with patterns cut-out. The spokes of a small wheel as well as a couple wheel rims sell the narrative of a busy operation. You can also spot carpentry tools and extra saw blades hanging behind the saw. The awesome roll-up garage door, neat little scaffold that the table saw operator stands upon when working, and the piles of sawdust complete the scene.

Removing the canopy roof on the pattern shop concrete dock reveals a fantastic scene. The table saw is used to cut the sides for the mold boxes which are then assembled for use in the casting process. The lumber stacked on the dock is consumed in the creation of the all important wood patterns. The patterns are the very foundation of the casting process. These patterns are stored for many years in the shop and are protected from fire by the roof mounted water tank. Looking closely at the dock, you will see plywood sheets with patterns cut-out. The spokes of a small wheel as well as a couple wheel rims sell the narrative of a busy operation. You can also spot carpentry tools and extra saw blades hanging behind the saw. The awesome roll-up garage door, neat little scaffold that the table saw operator stands upon when working, and the piles of sawdust complete the scene. The rear of the diorama features incredible detail which is a hallmark of all SierraWest kits. This is so important to me since I want you to have complete flexibility in placing my dioramas on your layout. In fact, most customers find it very difficult to choose a favorite side to display! The old blacksmith lettering is just visible above the large split doors. Talc, lime, and molding oil is delivered on the back dock. The hand operated swing boom aides loading and unloading materials from rail cars. The sand bay is such an extremely important detail. There's a lot of texture in such a small area including the stone and brick walls, heavy iron I-beam supports, and the sand. After delivery, the new sand is sifted then shoveled into the foundry for use in the casting process. Two small sand riddles used to sift the sand can be seen hanging in the bay.

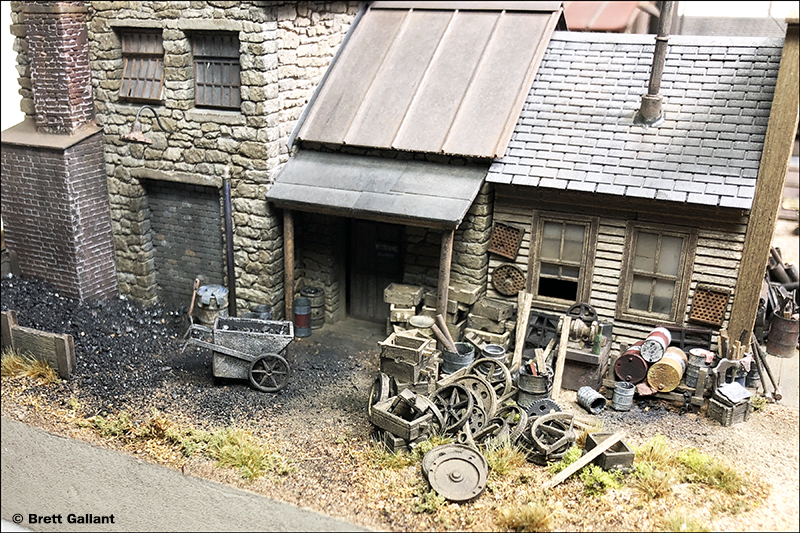

The rear of the diorama features incredible detail which is a hallmark of all SierraWest kits. This is so important to me since I want you to have complete flexibility in placing my dioramas on your layout. In fact, most customers find it very difficult to choose a favorite side to display! The old blacksmith lettering is just visible above the large split doors. Talc, lime, and molding oil is delivered on the back dock. The hand operated swing boom aides loading and unloading materials from rail cars. The sand bay is such an extremely important detail. There's a lot of texture in such a small area including the stone and brick walls, heavy iron I-beam supports, and the sand. After delivery, the new sand is sifted then shoveled into the foundry for use in the casting process. Two small sand riddles used to sift the sand can be seen hanging in the bay. I have saved my favorite scene for last. The foundry side features the coke bin and transport cart, piles of worn out discarded mold boxes, and old damaged wooden patterns. Study the scene closely to pick up all the fine details. Everything pictured except the scenery materials is included in the kit. You will also note the old sand riddles hanging on the office wall. These were once used to sift the sand in the foundry but have worn out. The doorway leading into the foundry was originally used to access the oil-fired brass furnace. When the iron cupola furnace was installed, they blocked up the doorway since the cupola sits just inside and added the bunker to store coke for the iron furnace. The pipe running just to the right of this old doorway transports oil from O’Neills for firing the brass furnace. I love all of the gritty old weathering featured in this scene. Like all of the techniques used, I paid special attention to creating reproducible results with a minimum of materials. Artist chalk, water based acrylic paint, and rubbing alcohol comprise the short list of supplies I used throughout the entire diorama.

I have saved my favorite scene for last. The foundry side features the coke bin and transport cart, piles of worn out discarded mold boxes, and old damaged wooden patterns. Study the scene closely to pick up all the fine details. Everything pictured except the scenery materials is included in the kit. You will also note the old sand riddles hanging on the office wall. These were once used to sift the sand in the foundry but have worn out. The doorway leading into the foundry was originally used to access the oil-fired brass furnace. When the iron cupola furnace was installed, they blocked up the doorway since the cupola sits just inside and added the bunker to store coke for the iron furnace. The pipe running just to the right of this old doorway transports oil from O’Neills for firing the brass furnace. I love all of the gritty old weathering featured in this scene. Like all of the techniques used, I paid special attention to creating reproducible results with a minimum of materials. Artist chalk, water based acrylic paint, and rubbing alcohol comprise the short list of supplies I used throughout the entire diorama.

The attention to the smallest detail is evident. The story telling is paramount in the development of each new kit. Instructions are provided leading you through every phase of construction including tool selection, assembly, weathering and aging, diorama composition, and scenery creation and application. It is of the utmost of importance to me that the techniques I develop and utilize are reproducible for modelers of all experience levels. When you view the pictures of Morton's remember this. SierraWest kits are unique in the level and amount of detail provided. Since all four sides are fully detailed, you have a ton of flexibility in placement and view-ability.

Here are just a few of the features of SierraWest kits:

- Award Winning Board on Board Modeling Techniques -

- Learn My Techniques for Multiple Types of Wood Siding,

Masonry, Windows and Doors, and Roofing Materials -

- Large Assortment of New Castings and Realistic Clutter -

- Unique, Incredibly Fine Laser Made Details -

- Comprehensive Fully Illustrated Instructions -

- Thoughtful Time-Tested Techniques that You

Can Replicate to Advance your Skills and Confidence -

- Industry First Laser Cut Jigs and Assembly Aids -

- Intricate Laser Cut Windows, Doors, and Wall Framing -

- Signs Meticulously Researched and Reproduced

for Historical Accuracy and Time Period -

- Metal Roofing, Laser Cut Shingles, and Tarpapers -